Industrial Laser Marking Systems / Laser Markers

Materials Suitable for UV Laser Marking and Engraving

UV laser marking is often a great choice for accurate and long-lasting marking on a variety of materials. A UV laser engraver delivers high-quality results with minimal heat impact, making it ideal for sensitive and delicate materials.

What is UV Laser Marking?

UV laser marking produces intricate, highly contrasted markings on various surfaces using a UV laser engraving machine. Cold marking is made possible by the short wavelength of UV light (usually 355 nm), which improves accuracy and guards against heat damage.

We’re here to provide you with more details.

Reach out today!

Benefits of UV Laser Marking for Different Materials

High precision and long-lasting markings that withstand wear, chemicals, and exposure to the environment are produced by UV laser technology. Reducing heat damage allows the cold processing method to guarantee that even delicate materials maintain their integrity.

Materials Ideal for UV Laser Marking and Engraving

UV laser marking and engrave marking offer exceptional results across a range of materials—from sensitive medical-grade plastics to tough industrial metals. This multipurpose technique is excellent at producing clear, long-lasting marks on fragile electronic circuits, polycarbonate parts, and even difficult materials like glass and ceramics. Because of its high absorption, it is especially useful for laser marking materials like PCB substrates, semiconductor components, and stainless steel medical devices.

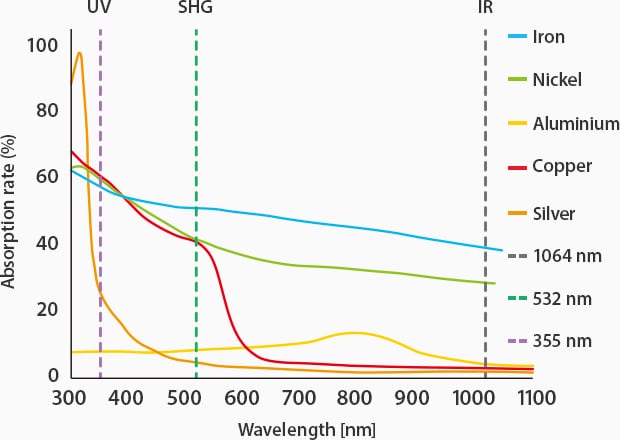

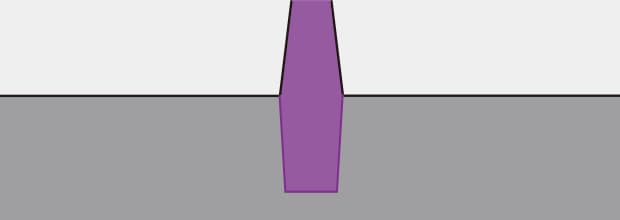

Light absorption rate for metal

Unlike other marking methods, UV lasers work with a remarkably light touch, allowing them to mark heat-sensitive materials like specialised polymers and coated surfaces without damage. The UV wavelength is particularly effective on these materials due to its short pulse duration and minimal heat. This unique capability has made a laser marker the preferred choice for industries that demand both precision and material compatibility.

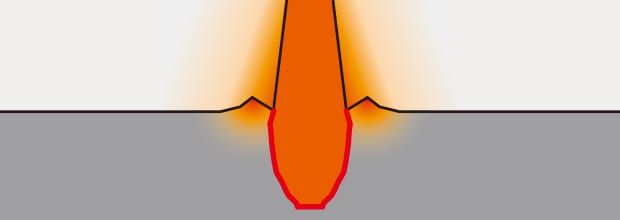

Standard Wavelength (Thermal Processing)

MD-U (Non-thermal Processing)

Marking Plastics with UV Lasers

Since plastics are frequently used in manufacturing, UV laser marking is a dependable way to create clear, sharp marks on them without causing any damage. Acrylic, polycarbonate (PC), polyethylene (PE), polypropylene (PP), and ABS are examples of common plastics. UV laser technology helps these materials in applications like logos, serial numbers, barcodes, and automotive or medical parts.

HDPE

Medicine bottles

Stainless Steel

Steel instruments

Glass

Windows

Nonwoven Fabric (PP/PE)

Masks

Discover more about this product.

Click here to book your demo.

Engraving Glass and Ceramics with UV Lasers

Glass and ceramics require precision marking without cracking or thermal stress. UV lasers can be used to create complex designs on mirrors, electronic displays, glass bottles, and medical equipment because they produce permanent, high-contrast marks.

Metal and Non-Metal Applications of UV Laser Machines

While fibre lasers are typically used for metals, UV laser engravers work exceptionally well on coated or treated metals like anodised aluminium, stainless steel, copper, and brass. On non-metallic materials like cardboard, paper, leather, and wood, they also work well.

For those interested in specialised applications, there are laser engraving machines designed specifically for metals such as brass and copper.

Final Thoughts

UV laser marking is a versatile, precise, and non-damaging method for engraving numerous materials. Whether you’re working with plastics, glass, ceramics, or metals, a UV laser engraving machine can provide high-quality results with long-lasting durability.

Businesses seeking advanced laser marking solutions can explore models like the KEYENCE MD-U1000.

If you still have questions about the suitability of a UV laser machine for your marking needs, view our laser marking resources or contact us today.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us