3D Scanner

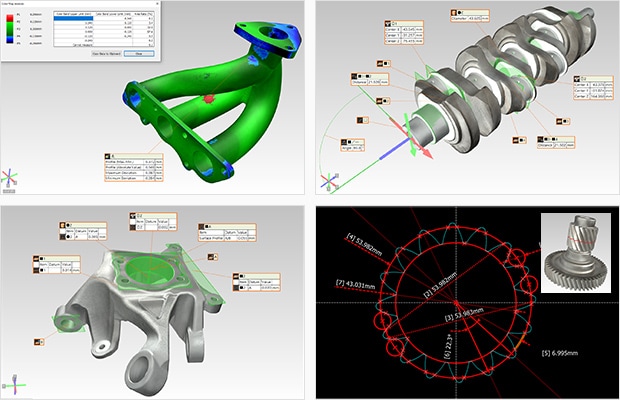

The KEYENCE 3D Scanner seamlessly moves between scanning, analysis, and STEP output. Data obtained from a 360° scan of the target can be superimposed on the CAD data for comparison. This scanner even allows for cross-sectional analysis. STEP output is available immediately after analysis, enabling prompt reverse engineering.

Products Lineup

The VL-800 Series 3D Scanner CMM is the first in its lineup to feature 3D-AI, making high-quality 3D data acquisition and analysis effortless for any user. The system intelligently recommends optimal scanning, stitching, and measurement methods based on the shape of the part being analysed. Additionally, scanned parts can be directly compared to their CAD models for quick visualisation of differences, or the 3D scan can be used to streamline reverse engineering processes. From scanning to STEP file output, the VL-800 handles everything automatically, and provides accurate data in a format accessible by any CAD software.

Features

High-Accuracy, Full 360° Scanning

The advanced structure of the VL-800 Series along with new AI software means that anyone can simply place a part on the stage and generate a 3D scan - no need for fixtures or reference targets/stickers. The software will automatically combine the scans into a complete 360⁰ model.

Flexible Measurement and Analysis of Any Shape

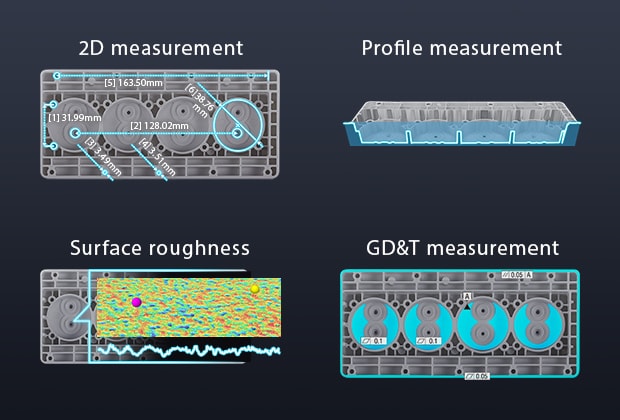

While conventional measurement systems such as profilometers or coordinate measuring machines measure using points or lines, the VL-800 is able to provide a full 3D scan of an object, giving users the ability to measure their parts in ways they never imagined.

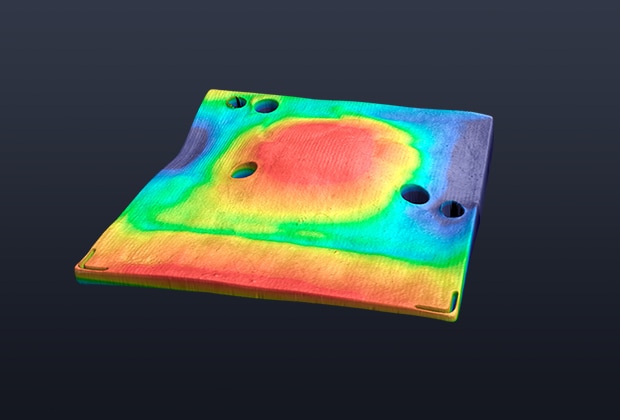

- Compare against 3D-CAD data to visualise differences

- 3D measurement tools for any geometric or freeform shape

- Automatically generated virtual cross-sections

- 12 different GD&T measurements

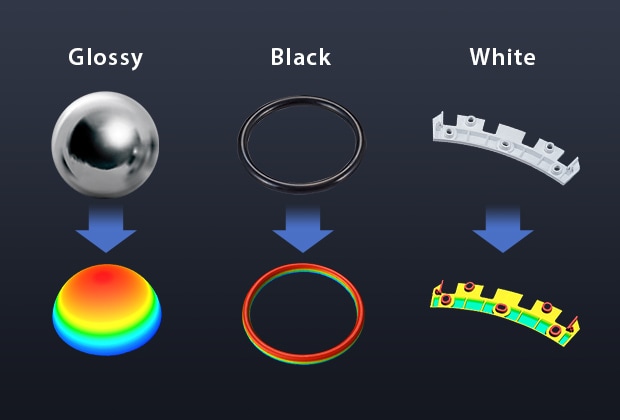

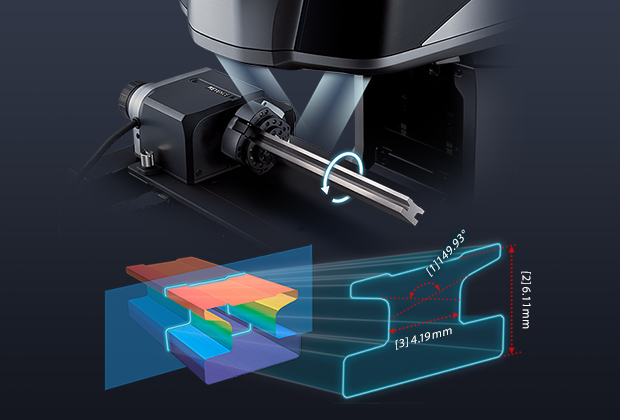

The VR-6000 optical profilometer performs non-contact measurement to replace stylus profilometers and roughness meters. This 3D profile system captures full surface data across the target with a resolution of 0.1 µm, enabling measurement of features that cannot be performed with probe-type instruments. The new rotational scanning greatly expands the measurement capabilities of the system. True-to-life cross section measurements can be performed with no blind spots. Wall thicknesses and recessed features can be measured without cutting or destroying the target. In addition, the HDR scanning algorithm provides enhanced scanning capabilities for instantly determining the optimal settings to capture high quality data, even on glossy and matte surfaces.

Features

Rotational Scanning on a Wide Variety of Materials

A 3D profilometer can be used for a wide range of applications across multiple industries. Examples of materials that can be analysed using a surface profiler include medical devices, jet engine turbine vanes for the aerospace sector, and valve trains found in automotive manufacturing. Using a 3D surface profilometer in these contexts means you can get accurate measurements of material thickness and detection of defects without the need for the instrument to come into contact with the object. Unlike conventional surface roughness profilometers, parts can be rotated to scan surfaces that would not be accessible otherwise. These qualities and capabilities make these devices ideal for collecting measurements and inspecting precision components such as batteries, circuit boards, and stamped metal parts.

HDR Scanning Algorithm Enables Measurement of More Materials

Automatic Rotation to Perform Measurements with No Blind Spots

Measure Nearly Any Callout with a Single Device

There are numerous measurements that can be taken with a 3D profilometer. For example, this system can be used to record the profile of a target by tracing its surface, enabling measurement of 3D features and surface roughness. It can also capture 2D data to measure lengths, widths, and angles. A 3D profilometer also creates a computer-generated 3D model of the object for visualisation of the overall shape, while still maintaining a high resolution to observe minute surface features.

Capture Full Surface Data with 0.1 µm Resolution in Just 1 Second

Consolidate Multiple Measurement Systems Into One Device