Flow Sensors

Products Lineup : Liquid Flow Rate

The FD-X Series flow sensors monitor low flow of any liquid by clamping directly on pipes or tubes up to 14mm.

Features

Utilize Everywhere

- Detect flow rates as low as 0.1 mL/min or shot amounts as low as 0.001 mL

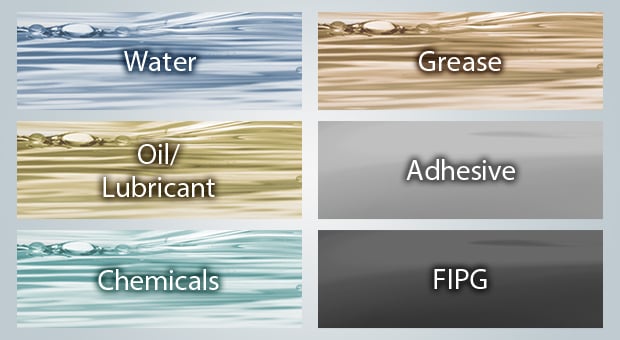

- Any liquid flow rate can be monitored including:

Viscous greases, chemicals, and sanitary liquids - Compatible with metal pipes and resin tubes from 3 mm - 12.7 mm

Zero Impact on Process

- Simply clamp the flow sensor to any pipe or tube

- Completely non-invasive

- No machine downtime or risk of clogging, pressure loss, or contamination

The FD-H Series clamp-on flow sensor is easily installed, without any pipe modification, by simply clamping to the outside of a pipe, tube or hose. This series provides stable flow rate measurement regardless of the pipe or liquid. In addition to metal and hard plastic piping, hoses (including high-pressure hoses) can also be supported. This product can not only measure the flow rates of various liquids such as water, DI water, oil, chemicals, and coolants but can also tolerate bubbles, high temperatures, and highly viscous liquids. Connecting a concentration sensor and temperature sensor allows for the centralised management of multiple parameters, helping improve product quality, and decrease costs.

Features

Countless Opportunities for Process/Machine Improvement

Supports Any Pipe, Type of Liquid, and Liquid Condition

KEYENCE clamp-on flow sensors perform detection from outside the pipe for a wide variety of applications. Now it is possible to monitor liquids with bubbles, high temperatures, and high viscosities.

Unmatched Features

A detachable display allows for remote monitoring while also clearly displaying current values, real-time graphs, historical data and more. Universal connectivity is achieved with a choice of control outputs, analogue outputs, and IO-Link. Additional features include high environmental ratings (IP65 & IP67), a built-in diagnostic function, and accuracy of 3% of R.D.

Extend Beyond Flow Sensing to Understand the Full System

Connecting other sensors to the FD-H Series allows for the continual recording and management of multiple parameters including liquid flow rate, concentration and temperature.

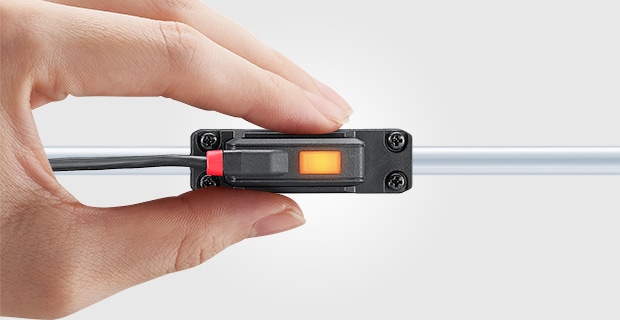

The FD-Q Series simply clamps-on to the pipe requiring no pipe modification and detects all sorts of liquid flow.

Features

Mounting and Integration

The FD-Q can be mounted in 60 seconds without any pipe modification. The unit clamps on to the outside of a pipe with 6 standard screws and can even be done without shutting the machine down.

Liquids and Pipes

The FD-Q series can detect virtually any type of liquid. This includes the flow of water (including deionised), oils, chemicals, consumer products, etc. This detection is possible through both metal and resin pipes.

Products Lineup : Gas Flow Rate

The compact case of the FD-EP Series houses a flow sensor and a pressure sensor, making it easy to diagnose the status of pneumatic equipment. The specialised application function makes real-time diagnosis and predictive maintenance of cylinders, suction transfer, seating and air blowers easy. The free flowing structure prevents pressure loss, clogging and supports both small and large flows. When selecting the sensor, just choose the one that matches your tube diameter. The high-definition display allows for intuitive operation with no need for an instruction manual. This one device can handle applications in which gases flow forward and backward such as cylinder forward and backward motion and the suctioning and vacuum release during suction transferring.

Features

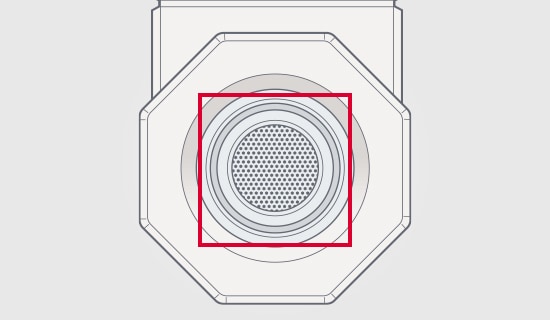

Zero Risk of Clogging

The FD-EP Series has a free flowing structure with no protrusions or obstructions in the flow path. Therefore, there is no need to worry about clogging or pressure loss caused by the flow sensor itself. Enjoy peace of mind throughout the installation process.

Conventional Unit

Pressure loss and clogging caused due to rectifier mesh plate inside.

FD-EP Series

Free flowing structure

There are no protrusions or obstructions that can cause pressure loss or clogging.

Selection Is Easy

Conventional air flow sensors have a different rated flow range depending on the model, even for the same tube diameter, making it very difficult to find the appropriate model for novel applications. The FD-EP Series can handle flows ranging from minute to large, eliminating the need to worry about the rated flow. Choosing a product is as easy as selecting the tube diameter.

Comparison of rated flow ranges (example with ø8 tube and fluid pressure of 0.4 MPa)

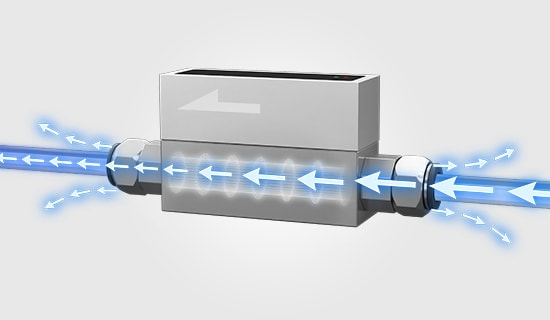

The FD-EC Series easily attaches to the outside of a tube, eliminating problems such as pressure loss and clogging, allowing for an uninterrupted supply of air. It can measure small and large flows and is compatible with various tube materials. When selecting the sensor, just choose the one that matches your tube diameter. The high-definition display allows for intuitive operation via the display amplifier, and diagnostic mode makes it possible to check the status while the sensor is attached to the tube. This sensor can detect gases regardless of the direction they flow, allowing for installations that fit the existing device layout.

Features

Zero Installation Risk

The FD-EC Series is free from all risks associated with conventional flow sensor installation, such as pressure loss, clogging, air leakage, or contamination. Also, because there is no need to cut tubes, the air supply does not need to be temporarily shut off during installation.

Conventional Unit

- Clogs due to multi-layer mesh structure

- Leaks from coupling

FD-EC Series

- Zero risk of pressure loss, clogging or contamination

- Zero air leakage

Ultra-Compact and Ultra-Lightweight

Air tubes are often thin, with limited space between tubes. The FD-EC Series is ultra-compact and clamps on for easy installation anywhere. The ultra-lightweight body also eliminates the need for mounting brackets.

High-density mounting is possible.

Products Lineup : Air Efficiency Module

MP-F Series simultaneously senses the flow, pressure, temperature and humidity of air. This can all be visualized along with energy consumption when the connected power monitor is used. This unit is equipped with a function that automatically records the air and electricity consumption (data that is vital when attempting to reduce energy consumption) at all times. The stored data can then be checked on the highly expressive multi display. Also, data can be analysed easily with the specialised PC software. The shut-off valve is an energy-saving feature that eliminates unnecessary air consumption by blocking air when the machine is not operating. This unit monitors the air status to detect problems such as pressure drops and condensation before they occur and notify the user of these errors.

Features

Visualise Air and Electricity Consumption

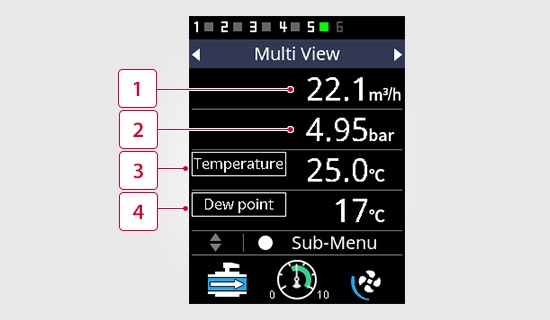

Easily visualise equipment energy consumption (air and electricity consumption*), which is important for energy conservation measures. The unit also has a “full-time recording function” that automatically records data on the main unit. Accumulated data can be viewed on an expressive multi-display.

*An energy monitor (MP-FEA1) and CT (MP-FEC) are required to measure electricity consumption

Flow × Pressure × Temperature × Humidity + Energy

The MP-F Series enables equipment energy consumption (air and electricity consumption) to be easily visualised, which is important for energy conservation measures. While doing this, the single unit can monitor air pressure, temperature, and humidity. Additionally, it comes with a shutoff valve that conserves energy by shutting off air leaks that can occur when the equipment is not in operation.

-

1Flow

-

2Pressure

-

3Temperature

-

4Humidity