Vision Sensor with Built-in AI

IV4 series

Vision Sensor with Built-in AI IV4 series

New The Next Evolution of AI is Here to Tackle the Most Difficult Detections

KEYENCE's next-generation AI is specifically designed to address current challenges in the detection and error-proofing market. This enhanced AI allows for quick, easy set up of the programme, and a stable, reliable solution.

Installed with the latest in Artificial Intelligence technology, the IV4 Series can now do more than ever. The IV4 Series can detect parts without using position adjustment, can check if the correct amount of parts are in their proper location, and can read and count targets under tough conditions. The IV Series is known for its simplicity and stability and the IV4 is stronger in these than ever before. Increased brightness, wide-and-narrow field-of-view options, and highly optimised built-in hardware mean that the IV4 is highly stable against environmental concerns like ambient lighting or slight finish changes. Even applications that are difficult for conventional vision sensors can be solved easily with the IV4 and its improved AI tools.

Features

Advanced Next-Generational AI Enables Powerful Yet Simple and Stable Detection

AI Identify

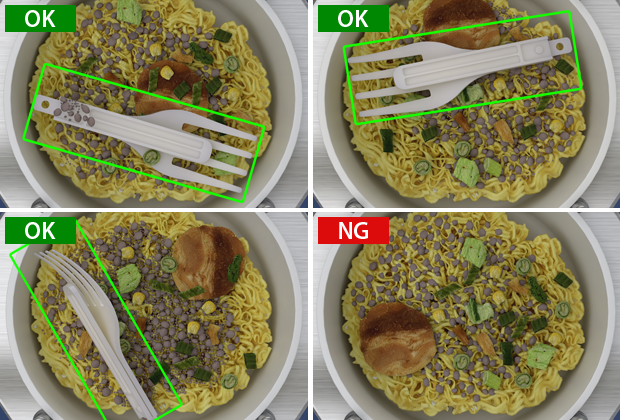

Confirming the presence of a fork in a container

No need to fix workpieces in place or use a positioning tool since the AI locates targets.

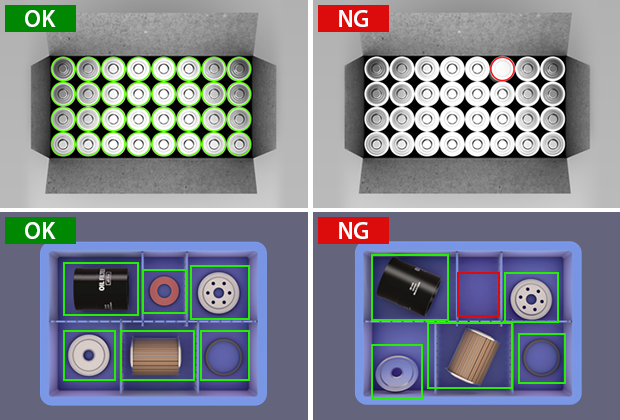

AI Count

Counting and front/back identification / Kitting management

Stable detection is possible for counting applications frequently used on production floors, including quantity/number checking, kit assembly, and production counting.

AI OCR

Narrow pitch / Metal engravings / Arced / SEMI font

All types of characters and prints supported, including embossed, engraved, laser-marked and ink-jet printed parts. Detection is not affected by individual target differences or environmental conditions.

AI Differentiate

Plastic bottle label differentiation / SMD resistor top/bottom differentiation

Sort and differentiate good and bad parts with just two images to set up. Equally effective with high-speed moving targets of even 250 parts/sec (4 ms).

Easy Setup

No matter how high-performance or stable a sensor may be, if operating the sensor is time-consuming or if configuration requires specialised skills, the sensor’s usability will be reduced. With the IV4 Series, setup can be completed in just 3 easy steps. Operation can be performed easily by anyone even without a manual.

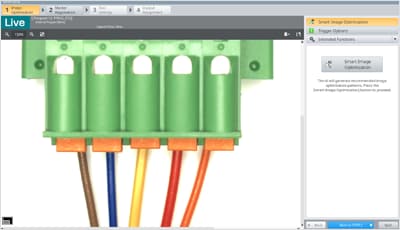

Step 1: Adjust Focus and Brightness

Using Smart Image Optimisation, focus and brightness are adjusted automatically. The process can be completed simply by selecting from a number of image candidates.

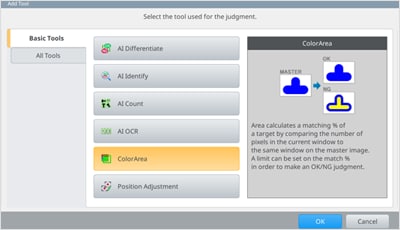

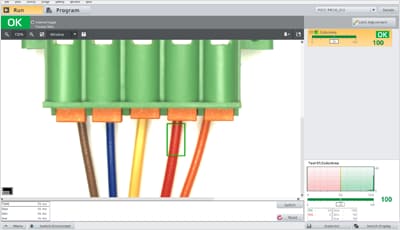

Step 2: Set Up Tools for Monitoring

Frequently used tools are displayed in obvious locations. Additional explanations are shown on the right-hand side of the screen to avoid confusion.

Step 3: Complete Setup

Check for problems with a trial run within the tool setup. If the tool is running as expected, move to the final step for output settings.

Extremely Easy Usability

Rich Lineup of Models

- Lighting, lens, camera... all-in-one. No specialised knowledge required

- Short or long range, narrow or wide FOV – every situation supported

- Usable for inspection of extremely small targets with optional magnifying lens attachment

Easy Installation

AI trigger

No trigger sensor needed for installation.

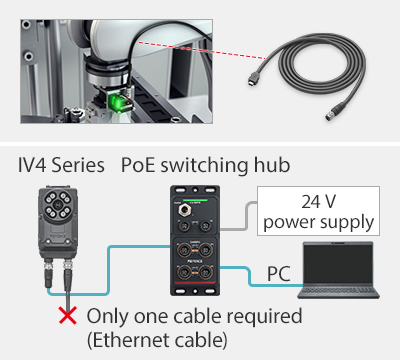

High-flex robotic cable / PoE (Power over Ethernet)-enabled

With a lineup that includes models with a high-flex robotic cable, a compact head, PoE support, and an IP67 enclosure rating, installation is possible even for a wide variety of site conditions.

3-way setup

The IV4 Series can be configured in one of 3 ways: using a dedicated panel, using a display, or using a PC.