Optimising the Measurement and Evaluation of Graphite Nodularity

Cast iron is a composite material in which the nonmetal graphite is distributed in a three-dimensional manner within iron. One such type is ductile cast iron, which has excellent mechanical characteristics due to the inclusion of nodules of graphite. As such, this type is used in automotive parts, infrastructure, etc. Measurement and evaluation of graphite nodularity and roundness factor in line with industrial standards are vital in guaranteeing these characteristics.

This section introduces how to determine the roundness factor and graphite nodularity as well as quantitative and efficient measurement examples using our latest 4K digital microscope.

- Evaluation with the Graphite Nodularity and Roundness Factor

- Determining the Graphite Nodularity and Roundness Factor

- Optimising the Measurement and Evaluation of Graphite Nodularity

- A 4K Digital Microscope That Supports and Optimises the Evaluation of Graphite Nodularity with a Single Device

Evaluation with the Graphite Nodularity and Roundness Factor

What is ductile cast iron?

Ductile cast iron (FCD material) is one type of cast iron that receives excellent mechanical characteristics through the development of graphite nodules. It is also called spheroidal graphite cast iron and nodular cast iron.

The difference between ductile cast iron and grey cast iron (FC material), which is a typical type of cast iron, is that the latter contains graphite flakes, making it fragile (giving it low toughness) because stress can easily focus on specific locations. On the other hand, ductile cast iron contains at least 0.04% Mg (magnesium) and at least 0.02% Ce (cerium) and 0.02% Ca (calcium), providing it with excellent mechanical characteristics such as wear resistance and tenacity (toughness) due to the crystalised nodules of graphite.

The main application of ductile cast iron is as the material in water, sewage, gas, and other pipes. It is also widely used in applications that require toughness and wear resistance such as automotive parts.

Graphite nodularity, roundness factor, and mechanical characteristics

For ductile cast iron and other nodular graphite cast iron products, the rate of graphite distribution (the graphite nodularity) and the roundness of the graphite nodules (the roundness factor) greatly affect mechanical properties such as wear resistance, toughness, tensile strength, and ductility.

Therefore, it is very important to measure and evaluate the graphite nodularity and roundness factor in a quantitative manner during evaluations of ductile cast iron in order to guarantee its quality and characteristics.

Determining the Graphite Nodularity and Roundness Factor

Graphite nodules do not form as perfect spheres. Therefore, to measure the graphite nodularity, it is necessary to define nearly spherical shapes as nodular graphite and to differentiate these shapes. Generally, the roundness of an object’s shape is evaluated using circularity, but with graphite nodularity, the roundness factor—which has a different concept from circularity—is used to classify the roundness according to a standard and is applied to a formula to calculate and evaluate the roundness.

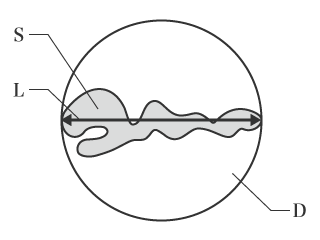

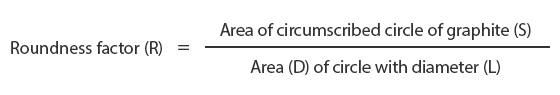

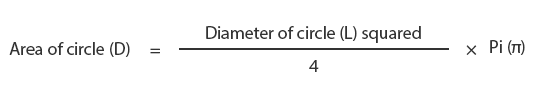

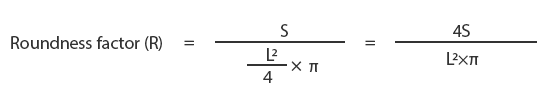

Determining the roundness factor

The roundness factor (R) used to evaluate graphite nodularity is determined by observing the graphite in the material as shown in the figure. L is the maximum diameter (long axis) of the graphite. S is the area of the graphite, and D is a circle with this maximum diameter used for its diameter. Dividing the area of S by the area of D gives the roundness factor.

In other words, the relationship between these values is as follows.

Combining these formulas results in the following formula for determining the roundness factor.

Determining the graphite nodularity

Roundness factor classifications and size classes, both standardised by an industrial standard, are used to determine the graphite nodularity. Classifications and standards according to ISO 945 and the way to use them to calculate the nodularity are introduced below.

The following information conforms to the ISO standard, but the appropriate standard may be subject to revision. Be sure to also check the latest standard.

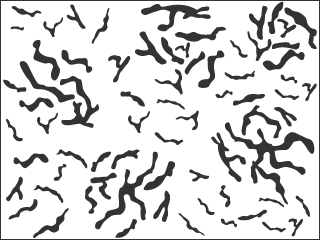

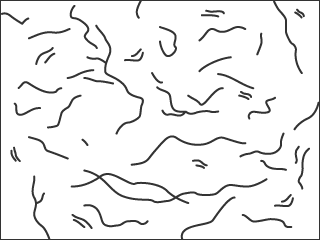

- Roundness factor classifications

-

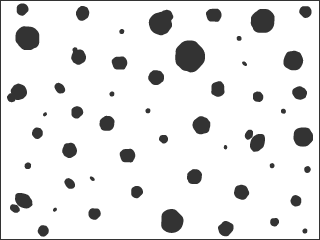

VI:Spheroidal graphite

VI:Spheroidal graphite

Roundness factor: R ≥ 0.80 -

V:Slightly irregular spheroidal graphite

V:Slightly irregular spheroidal graphite

Roundness factor: 0.60 ≤ R < 0.80 -

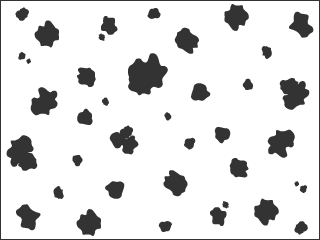

IV:Irregular spheroidal graphite

IV:Irregular spheroidal graphite

Roundness factor: 0.45 ≤ R < 0.60 -

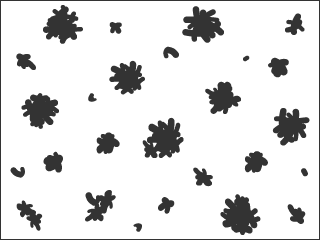

III:Vermicular (compacted) graphite

III:Vermicular (compacted) graphite

Roundness factor: 0.10 ≤ R < 0.45 -

I:Lamellar (flake) graphite

I:Lamellar (flake) graphite

Roundness factor: R < 0.10

- Size class classifications

-

Class Graphite size (mm) 1 Greater than or equal to 1 2 Greater than or equal to 0.5 and less than 1 3 Greater than or equal to 0.25 and less than 0.5 4 Greater than or equal to 0.12 and less than 0.25 5 Greater than or equal to 0.06 and less than 0.12 6 Greater than or equal to 0.03 and less than 0.06 7 Greater than or equal to 0.015 and less than 0.03 8 Less than 0.015 -

According to the ISO, graphite less than 10 µm in size is not counted.

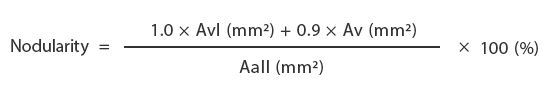

- Calculating the graphite nodularity

- To calculate the graphite nodularity, divide the area of the graphite having a size of 10 µm or more and classified as V or VI from the roundness factor by the total area of all graphite having a size of 10 µm or more.

The formula to use in determining the nodularity and the values to substitute are explained below. -

AvI:Area of the graphite having at least the minimum size (10 µm) and classified as VI with the roundness factorAv:Area of the graphite having at least the minimum size and classified as V with the roundness factorAall:Total area of all the graphite having at least the minimum size

AvI:Area of the graphite having at least the minimum size (10 µm) and classified as VI with the roundness factorAv:Area of the graphite having at least the minimum size and classified as V with the roundness factorAall:Total area of all the graphite having at least the minimum size

Optimising the Measurement and Evaluation of Graphite Nodularity

Deriving the graphite nodularity using an optical microscope requires complicated operations such as classification via measurement and calculation of the roundness factor, area calculation, and counting. However, not only are these operations time- and labour-intensive, but they are also prone to human error and were difficult to evaluate quantitatively.

Even when performing image analysis with PC software, time and effort are required to capture clear magnified images of graphite with an optical microscope. The resulting problem is that operations such as managing the large amount of image and numeric data and creating reports with this data are complicated.

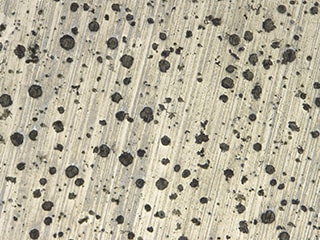

KEYENCE’s ultra-high accuracy VHX Series 4K digital microscope is equipped with a high-resolution HR lens and a 4K CMOS image sensor, enabling it to capture high-resolution 4K images of graphite nodules having various shapes and sizes. The area of the graphite can be calculated and the number of these nodules can be counted automatically from these high-accuracy images. Clear images and accurate values can be output in Excel format, leading to overwhelming efficiency in the report creation process.

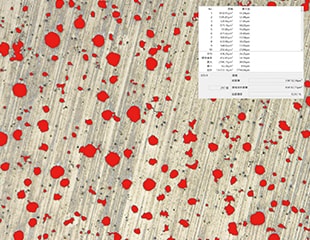

Automatic area measurement/count of graphite nodularity

The VHX Series 4K digital microscope’s observation system provides a large depth of field, allowing for easy capturing of images that are focused throughout the field of view. Hence, clear 4K images of the shapes of the graphite included in the sample can be captured. These high-accuracy images can be used to seamlessly and automatically measure the area of the graphite and count the number of nodules with high accuracy, allowing for prompt acquisition of quantitative analysis results.

This automatic area measurement/count function allows for prompt automatic acquisition not only of the count and area of objects determined to be graphite nodules under specified conditions but also of a variety of data such as the total area; the total area ratio; and the maximum graphite diameter as well as its average, standard deviation, maximum value, and minimum value.

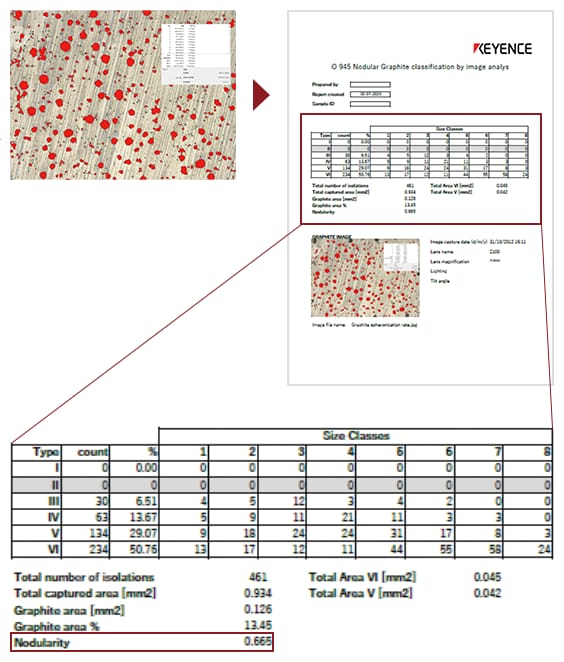

Optimising report creation for graphite nodularity

The VHX Series 4K digital microscope can not only automatically measure graphite nodules with high accuracy but can also automatically create reports using the acquired image and numeric data.

Because Excel can be installed directly on the VHX Series, there is no need to use a PC. Data can be output directly to reports. Output analysis data to a template matching the application to automatically calculate and display values in line with the standard. The images to be analysed can even be laid out automatically.

The following image shows an example of using a single VHX Series to acquire a graphite observation image and the analysis data and output them to an Excel template. This example indicates how an ISO-compliant report containing roundness factor classifications (type) and size classes, nodule counts, various area measurement results, and graphite nodularity can be created automatically.

Automatic report creation greatly reduces the time and effort required to perform analyses and calculations and to manage data.

A 4K Digital Microscope That Supports and Optimises the Evaluation of Graphite Nodularity with a Single Device

The VHX Series 4K digital microscope can easily acquire accurate data by capturing clear, high-resolution 4K images and using these images for highly accurate automatic area measurement and counting. This one device can support all the steps required for the evaluation of graphite nodularity, including the output of reports showing items matching industrial standards.

Problems are not limited to how time- and labour-intensive the work is. The risks of human error and variations in measured values obtained by different operators are present in the visual checks and measurement of graphite as well as in the manual entry of values, all of which require operators to have a certain level of proficiency.

The quantitative measurement and evaluation of graphite nodularity are often complicated processes, but installing the VHX Series easily supports these operations with a single device, saving you a large amount of time and effort.

For additional product info or inquiries, click the buttons below.