Causes, Observation, and Measurement of Connector Problems Such as Defective Continuity

Connectors, which are now in high demand and come in a wide variety of types, are required to have high quality. This section explains the causes of problems such as corrosion, oxidisation, wear, adhesion of foreign particles, solder defects, tin whiskers, and migration that can lead to defective continuity, defective insulation, and connector contact failure. Solutions for these problems are also explained.

This section also introduces application examples of KEYENCE’s latest 4K digital microscope, which solves the conventional problems indispensable in defect analysis and quality inspection and enables clear observation, 3D measurement, and quantitative evaluation of three-dimensional connectors.

- Diversified Connector Types and the Importance of Quality

- Typical Connector Problems, Causes, and Solutions

- Problems in Connector Observation and Evaluation and Application Examples of the 4K Digital Microscope

- High-resolution observation of industrial connector terminals

- Evaluation of connector pin shapes

- Observation of deep connectors and terminals

- Observation of plated crimping terminals and connector pins

- Evaluation of cross-section samples of resin-embedded connector pins

- Observation of dents on plated surfaces

- Measurement and quantitative evaluation of solder defects on connector electrodes

- The Optimal Microscope for Observation, Measurement, and Evaluation of 3D Connector Shapes

Diversified Connector Types and the Importance of Quality

There is an increasing demand for connectors in response to the recent expanded use of digital and communication devices. The types and applications of connectors are also increasing.

One typical connector is the USB connector, which has a variety of types and is widely used to, for example, connect computer peripherals and charge portable devices. For communication, the RJ-45 connector, which is used in LAN connections, and LC/SC connectors, which are used in optical fibre connections, are available. Other connectors include the XLR, phone, and RCA connectors, which have long been used for sending analogue audio signals, and the HDMI and VGA connectors, which have become mainstream for sending digital video signals to displays and monitors.

In addition to connectors for consumer use, many general-purpose and special-purpose connectors are used in various industrial fields. Contact failures, defective continuity, and defective insulation caused by defective connectors may not only lead to complaints from consumers but may also prevent professionals from completing their tasks.

Connectors are also used in special electrical parts, such as wiring harnesses in automobiles where important components are increasingly controlled electronically. Any defects and corrosion of such connectors can lead to accidents. This is why high quality and reliability are required for connector products.

Typical Connector Problems, Causes, and Solutions

The following are typical connector problems that can cause contact failures, defective continuity, and defective insulation and consequently impair quality and performance of connectors and solutions for such problems.

- Corrosion/Oxidisation

- Phenomenon: This problem occurs when nickel, copper, or other metal in the base metal corrodes and separates to form a deposit on the surface.

Possible causes: High temperature, high humidity, and corrosive gases

Action: Plate the connectors with gold or apply a corrosion and oxidisation inhibitor.

- Wear

- Phenomenon: This problem occurs when vibration or impact causes contacting parts to slide and subsequently wear down.

Possible causes: Vibration, impact, very frequent insertion and removal

Action: Use a connector with high contact pressure and wide contact surface.

- Adhesion of Foreign Particles

- Phenomenon: This problem occurs when foreign particles stick to the connector and obstruct electrical conduction.

Possible causes: Intrusion of gas or fine particles into the connector

Action: Increase the degree of sealing and airtightness.

- Solder Defects

- Phenomenon: This generic term refers to defective insulation or defective continuity caused by improper application of solder.

Possible causes: Solder fractures or cracks, solder balls, solder bridges, and other defects

Action: Review the heating temperature and time for the solder.

- Tin

- Phenomenon: This problem occurs when tin in the plating crystallises in the form of whiskers and grows. Tin whiskers cause insulation to break down as indicated by short circuiting.

Possible causes: Metal internal stress

Action: Plate the connectors with gold.

- Migration

- Phenomenon: This problem occurs when metal components travel on the insulator and cause dielectric breakdown.

Possible causes: High temperature, high humidity

Action: Apply a damp-proof coating such as fluorine film.

Problems in Connector Observation and Evaluation and Application Examples of the 4K Digital Microscope

In recent years, connectors have become smaller and diversified and have achieved higher functionality, but some products become popular and obsolete very quickly. For example, the demand for one type of connector can rapidly change when a hit product starts using or no longer uses that type of connector. To respond to such rapid changes in demand, in addition to research and development of new products, established manufacturing processes and accurate and quick quality control and assurance become important in many cases.

KEYENCE has repeatedly improved and reformed its products for over 30 years in the field of digital microscopes by making use of the information obtained from on-site customers.

The result of this process is the VHX Series high-definition 4K Digital Microscope, which provides additional features and functions for improving workflow efficiency.

This section introduces the latest examples of connector observation, analysis, measurement, and evaluation using the VHX Series.

High-resolution observation of industrial connector terminals

The VHX Series 4K Digital Microscope uses high resolutions that support 4K images, a high-resolution lens that provides a deep depth of field, and a high-resolution and low-noise 4K CMOS.

This allows users to capture high-resolution images that are fully focused on connector terminals having complex, three-dimensional shapes. Details that previously could not been seen can be observed and analysed with clear images.

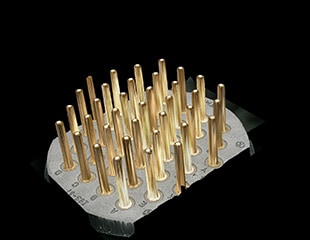

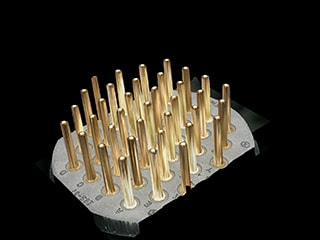

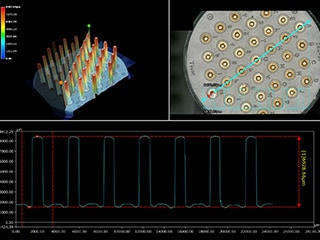

Evaluation of connector pin shapes

The VHX Series 4K Digital Microscope immediately creates a fully focused image of a three-dimensional connector having multiple pins by composing multiple images having different focus positions.

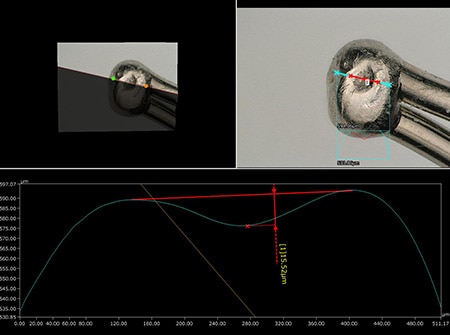

When displayed in 3D, the shapes of such three-dimensional connector pins can be observed freely from various angles. The image is also displayed with a highly accurate height colour map, which easily visualises 3D shapes and enables profile measurement of a specified area.

With the VHX Series, a single unit is all that is needed to quickly complete an entire series of work operations from magnified observation and 3D measurement for quantitative evaluation of pin shapes to automatic report creation using observation images and measured values with a template. This streamlines the conventional inspection procedures, thus significantly reducing working hours.

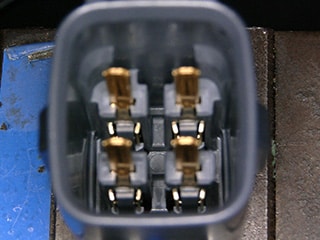

Observation of deep connectors and terminals

Some industrial connectors in a long housing or shield have pins and terminals in the recessed areas.

The VHX Series 4K Digital Microscope uses a lens that has a deep depth of field and real-time depth composition, thus easily enabling fully focused imaging even on three-dimensional objects. This improves the efficiency of the inspection procedure and eliminates blind spots.

Furthermore, using the free-angle observation system enables tilted observation from any angle without the need to reset the target on the stage. Even long connectors can be observed quickly at the optimal angle.

Observation of plated crimping terminals and connector pins

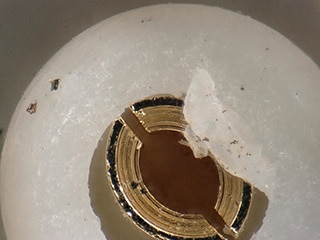

Some connector pins and terminals are gold-plated to prevent defective continuity and defective insulation caused by corrosion, oxidisation, or tin whiskers. Reflective shiny plated surfaces, however, often have glare, making it difficult to observe and evaluate the surface conditions correctly.

The VHX Series 4K Digital Microscope has glare removal and ring-reflection removal functions. It is possible to clearly observe the surface conditions of plated connector pins and the crimping conditions of terminal core wires even when they are highly reflective and many tiny parts are gathered.

right: glare and ring-reflection removed (200x)

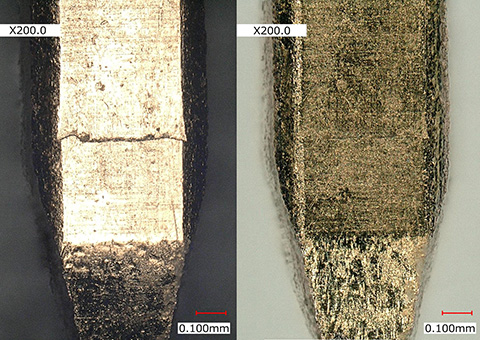

Evaluation of cross-section samples of resin-embedded connector pins

The VHX Series 4K Digital Microscope creates a high-resolution image of a wide area with up to 50,000 × 50,000 pixels through high-speed image stitching. Just pushing the image stitching button will easily and quickly stitch together high-magnification images automatically with no misalignment.

If a cross-section sample has surface irregularities due to insufficient polishing after resin embedding, the depth composition provides a fully focused bird’s-eye view. This allows users to observe and evaluate details of the target on a high-resolution image at high magnification while tracking the measurement points on the entire image.

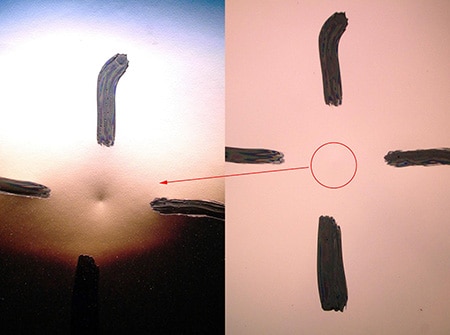

Observation of dents on plated surfaces

A connector is comprised of various materials such as metal and resin. It is difficult to determine the lighting conditions for an area that includes highly reflective portions, such as plated surfaces and copper foil tapes, because glare from such shiny surfaces interferes with the observation of dents and other defects.

The VHX Series 4K Digital Microscope has a multi-lighting function, which automatically captures the data of multiple images under omnidirectional lighting at the push of a button. Then, the image most suitable for observation can be selected from among the captured images, which significantly improves work efficiency and observation accuracy. Even dents, for which it was difficult to determine the observation lighting conditions, can now be observed easily.

Furthermore, image data with different lighting is automatically saved even after the observation image is selected, so other images with different lighting conditions can be loaded immediately when needed. This ability to load other images eliminates the need to place the sample on the stage again and reproduce the settings when it is necessary to perform observation with a different point of view.

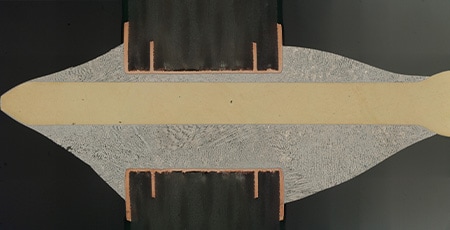

Measurement and quantitative evaluation of solder defects on connector electrodes

Solder defects, such as pits and cracks, on connector electrodes can not only cause defective continuity but also increase the resistance at the defective points. The increased resistance can then cause joule heating, resulting in heating and ignition at the defective points. Conventional methods, however, cannot quantitatively evaluate the defects due to glare from the solder.

The VHX Series 4K Digital Microscope has glare removal and ring-reflection removal functions, thus enabling observation of defective areas with clear images having no glare. The captured observation images can also be used for high-accuracy 3D shape measurement and profile measurement in a specified area. Such measurements enable quantitative measurement and evaluation of defective areas with higher efficiency.

The Optimal Microscope for Observation, Measurement, and Evaluation of 3D Connector Shapes

The VHX Series 4K Digital Microscope improves your work by clearly observing 3D shapes—such as connectors and their component parts and internal structures—and accurately measuring them with ease and speed.

Another outstanding feature is its highly usable interface and highly efficient operations developed from the information obtained from on-site customers. The VHX Series does not require time-consuming sample preparation to observe and analyse surfaces.

The VHX Series is also equipped with many other functions in addition to those introduced here. For product details, click the button shown below to download the catalogue. For inquiries, click the other button shown below to contact KEYENCE.