The Latest Observation and Analysis of Lithium-ion Batteries and Next Generation Batteries

With the growing demand for applications in electrical and electronic equipment, such as smaller and thinner electronic devices, in-vehicle batteries that require large capacities and safety, and residential energy storage systems, lithium-ion batteries have become an important industrial field. The storage capacities and charging speeds of lithium-ion batteries have seen increasing improvements. At the same time, these batteries have risks that cannot be overlooked such as ignition and the generation of heat and smoke. To reduce these risks, it is important to ensure safety in research, development, quality assurance, and quality control.

Also, observation, analysis, evaluation, and report creation need to be performed as quickly as possible in this industry because of the fast product cycle due to intense competition. This section explains basic knowledge of lithium-ion batteries, much-discussed next generation batteries, and examples of the latest observation and analysis that greatly improve efficiency.

- Basic Structure, Types, and Materials of Lithium-ion Batteries

- Problems in the Observation and Analysis of Secondary Batteries Such as Anticipated Next Generation Batteries and Lithium-ion Batteries

- The Latest Applications of Our 4K Digital Microscope That Improves the Efficiency of Observation, Analysis, and Evaluation of Lithium-ion Batteries

- A 4K Microscope That Optimises Research, Development, Quality Assurance, and Quality Control of Secondary Batteries

Basic Structure, Types, and Materials of Lithium-ion Batteries

Lithium-ion batteries, which are secondary batteries called LiBs for short, are commonly used for various products, such as smaller and thinner electronic devices including smartphones, tablets, wearable devices, and laptop computers; in-vehicle batteries for electric vehicles (EVs) and hybrid electric vehicles (HEVs); and power storage systems for residential photovoltaics and fuel cells. With the expanded applications, lithium-ion batteries are now manufactured to have various structures and shapes. Read on for explanations of the basic structure, typical shapes, and some other related items of lithium-ion batteries.

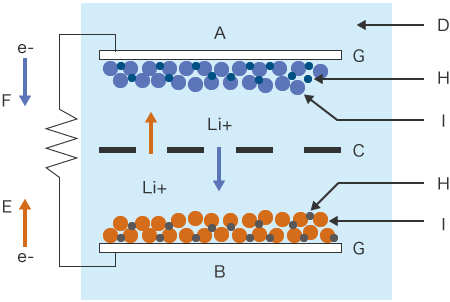

Basic structure of lithium-ion batteries

Each part of a lithium-ion battery, including their functions, is explained here with a figure showing a typical example of the basic structure of these batteries.

- A) Negative electrode (cathode): Highly conductive carbon-based materials (graphite, lithium titanate, etc.) are coated onto copper foil.

- B) Positive electrode (anode): Lithium composite oxides (lithium, manganese, cobalt, nickel and iron phosphate, etc.) are coated onto aluminium foil.

- C) Separator: This is a microporous membrane made from a chemical compound called polyolefin (examples of which include polyethylene [PE] and polypropylene [PP]). The membrane has small holes (1 micrometre or less) on the surface. The separator isolates the positive and negative electrodes and prevents fires caused by them coming into contact.

- D) Electrolyte: Lithium salt is dissolved in an organic solvent.

- E) Charge

- F) Discharge

- G) Current collector: Plays the roles of an electrical conductor to collect the generated electricity and of a support material. The positive electrode is aluminium foil, and the negative electrode is copper foil.

- H) Binder: Used to bond mixed materials on the current collector foil.

- I) Active material: Significantly affects the capacity, voltage, and characteristics. There are various materials to use (such as lithium cobalt oxide, lithium manganese oxide, and lithium iron phosphate), mixing ratios, and stirring methods.

Shapes and forms of lithium-ion batteries

Cells of lithium-ion batteries, which have the internal structure introduced above, are covered with cases in various shapes and forms made from different materials. Three representative shapes (forms) of lithium-ion batteries are explained below with figures.

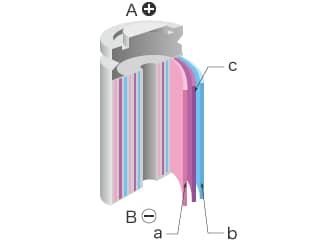

- Cylinder type

-

- A: Positive electrode terminal

- B: Negative electrode terminal

- a: Positive electrode

- b: Negative electrode

- c: Separator

Cylindrical lithium-ion batteries are believed to have the highest capacity density at the lowest cost. However, when multiple cells are combined in a case, gaps are left between the cells, decreasing the density.

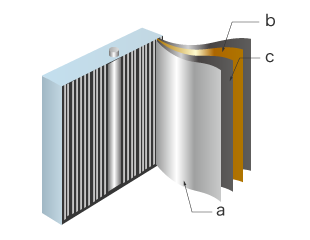

- Prismatic type

-

- a: Positive electrode

- b: Negative electrode

- c: Separator

Aluminium cases are often used for prismatic lithium-ion batteries. The polarity of a prismatic battery changes according to the case material, iron or aluminium. An iron case has the positive terminal on the top while an aluminium case has the negative terminal on the top.

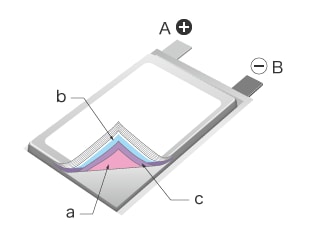

- Laminated type (lithium polymer battery)

-

- A: Positive electrode terminal

- B: Negative electrode terminal

- a: Positive electrode

- b: Negative electrode

- c: Separator

The laminated type is also called a lithium polymer battery. Because using a cell laminated with films can reduce the thickness of the battery, this type is used for devices that need to be thinner, such as smartphones and tablets.

Typical electrolytes used for this type are gels containing polymers such as polyethylene oxide (PEO), polypropylene oxide (PPO), and polyvinylidene difluoride (PVDF).

Types and characteristics of materials used for positive and negative electrodes of lithium-ion batteries

The characteristics, applications, and even costs change according to the materials used for the positive electrode or negative electrode of lithium-ion batteries. Read on for an introduction to some typical types and their characteristics.

- Cobalt base

Positive electrode: Lithium cobalt oxide LiCoO2/Negative electrode: Graphite LiC6 - The most commonly used lithium-ion batteries, which are widely used mainly in mobile devices. But cobalt is expensive and there is the risk of thermal runaway, so they present safety concerns for use in vehicles.

- Nickel base

Positive electrode: Lithium nickel oxide LiNiO2/Negative electrode: Graphite LiC6 - Nickel-based lithium-ion batteries have the largest capacity. There used to be safety concerns regarding this type. However, the NCA base, produced by substituting cobalt for a part of the nickel and adding aluminium, has improved the safety of this type, making it possible to be used in plug-in hybrid electric vehicles.

- Manganese base

Positive electrode: Lithium manganese oxide LiMn2O4/Negative electrode: Graphite LiC6 - Manganese-based lithium-ion batteries (LMO base) are most commonly used in vehicles because manganese is cheap, approximately a tenth of cobalt, and its rigid crystal structure is very safe because it has high thermal stability.

- Iron phosphate base

Positive electrode: Lithium iron phosphate LiFePO4/Negative electrode: Graphite LiC6 - Lithium-ion batteries using iron phosphate have a crystal structure that is very safe because it is difficult to break even when heated in batteries. Another advantage is that this type can be manufactured at costs even lower than manganese-based batteries that use iron. A disadvantage of this type is its low energy density.

- Three-component base

Positive electrode: Nickel and manganese are substituted for a part of lithium cobalt oxide Li(Ni-Co-Mn)O2/Negative electrode: Graphite LiC6 - Three-component lithium-ion batteries, also called NCM-based batteries, use three components—cobalt, nickel, and manganese—to increase safety. As with NCA-based batteries, this type is used in plug-in hybrid electric vehicles.

- Titanic acid base

Positive electrode: Lithium manganese oxide LiMn2O4/Negative electrode: Lithium titanate Li4Ti5O12 - Titanic acid-based lithium-ion batteries have long service lives that are approximately six times longer than conventional lithium-ion batteries using graphite for the negative electrode and also charge very quickly. However, they have low energy density, which is a disadvantage.

Problems in the Observation and Analysis of Secondary Batteries Such as Anticipated Next Generation Batteries and Lithium-ion Batteries

In parallel with modifications and performance improvements of lithium-ion batteries, each manufacturer is promoting the development of the next generation of secondary batteries. Read on for an introduction to the types and characteristics of representative next generation batteries that are expected to become available and popular. A summary of the problems in the observation and analysis in the secondary battery industry where manufacturers are competing fiercely is also provided.

Next generation batteries that are expected to become available and popular

With expanded applications such as usage in electric vehicles (EVs), next generation secondary batteries are expected to be even safer and have even larger capacities. Many companies, regardless of their scale, are working on researching and developing next generation secondary batteries as a way to improve their business future. Read on for an introduction to representative next generation secondary batteries.

- Lithium-air battery

- Some studies suggest that capacity density can, in theory, exceed 10,000 Wh/kg. In the tests, this characteristic has been confirmed to reach approximately 600 Wh/kg. However, it is easy for deposits to form on lithium metal, which is used for the negative electrode. As such, the safety of this metal may decrease and its characteristics may deteriorate when it reacts with moisture in the air.

- Solid-state battery

- A solid-state battery uses a solid electrolyte as the separator instead of the liquid electrolytes used in lithium-ion batteries. This allows solid-state batteries to be manufactured in various shapes and to be free of fluid leakage. The theoretical capacity density is believed to be at least 2000 Wh/kg. This is, however, only a theoretical value. Research and development are currently ongoing with the goal of putting this type of battery into practical use with the target capacity density of 500 Wh/kg or more. This type of battery can charge and discharge at high speeds and is hard to deteriorate even after many charge cycles.

Solid electrolytes are available in two types: sulphur base and oxygen base. The sulphur-based electrolyte has superior characteristics, but poses the risk of generating hydrogen sulphide when ignited or reacted with water. Manufacturing of solid-state batteries has started with small ones for electronic devices.

- Next generation lithium-ion battery

- Silicon and graphene are used for the negative electrode. This type of battery is being researched and developed to increase the capacity while existing manufacturing processes are used. A research item that is gathering attention is the fact that changing to different electrolytes can increase the charging and discharging speeds.

- Lithium-sulphur battery

- Lithium-sulphur batteries can have a capacity density of 2500 Wh/kg in theory, which is higher than solid-state batteries, and use no expensive materials such as cobalt. With these features, large capacities at low costs can be expected. At the same time, lithium-sulphur batteries have low conductivity and low stability and can deteriorate when charged many times.

- Sodium-ion battery

- Although the capacity density is equal to or slightly less than that of current lithium-ion batteries, sodium-ion batteries can be manufactured at low costs because no rare metal is required and existing manufacturing equipment can be applied. As with existing lithium-ion batteries, sodium-ion batteries have concerns regarding safety, such as high reactivity of sodium deposits, and their characteristics can deteriorate after many charge cycles.

Problems in the observation and analysis of secondary batteries such as lithium-ion batteries

Manufacturers are competing to research and develop safer lithium-ion batteries having higher performance. Quality assurance and control are required for a fast product cycle. Furthermore, in research, development, and patent application regarding next generation batteries, many companies and researchers are competing every day to produce superior technologies.

Therefore, observation, analysis, quantitative evaluation, and even the speed of these operations are important and can be key success factors for both testing and quality assurance in the research, development, and improvement of secondary batteries.

At the same time, observation and analysis using optical microscopes have the following problems.

- Focus adjustment and lighting condition determination are difficult for three-dimensional targets or targets having subtle scratches with low contrast. On these targets, the focus position varies from operator to operator, resulting in errors in evaluation results.

- Glare may occur during observation of areas containing a mix of materials having different glossy surfaces. It is difficult to determine the lighting settings appropriate to observe these targets, often causing mistakes in analysis.

- It takes time and effort to align a sample and change the angle.

- To count contaminants and closely observe foreign particles according to applicable industrial standards, setup can be cumbersome, requiring a lot of time and effort. Additionally, a high level of expertise is required to acquire accurate analysis results and quantitative values.

- Measured values and counts are not stored as numeric data, which requires a lot of time and effort for subsequent work such as analysis, evaluation, and report creation.

Read on for an introduction to examples of quick and accurate observation and analysis with simple operation using the latest 4K digital microscope that solves the above problems.

The Latest Applications of Our 4K Digital Microscope That Improves the Efficiency of Observation, Analysis, and Evaluation of Lithium-ion Batteries

With the recent technological progress of digital microscopes, the problems involved with optical microscopes can be solved and each part of a secondary battery can be observed more quickly and clearly with simple operations even at high magnifications. The latest digital microscopes can greatly improve work efficiency of dimensional measurement, contamination (foreign particle) analysis, report creation using images and numeric data, and other related operations.

KEYENCE’s VHX Series 4K digital microscope can capture clear images and measure dimensions using high-resolution HR lenses, a 4K CMOS image sensor, lighting, and image processing technology, enabling observation, analysis, and evaluation of secondary batteries with higher efficiency.

Read on for introductions to examples of observation and analysis of lithium-ion batteries using the VHX Series.

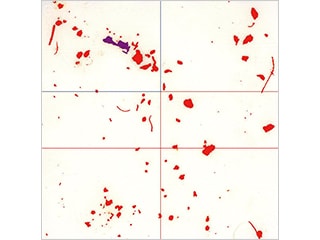

Counting of foreign particles (contamination analysis that complies with the ISO standards)

The VHX Series can measure contamination according to the ISO 16232 and VDA 19 automotive industry cleanliness standards. This product is equipped with the accurate automatic area measurement/count function that uses high-resolution images having a large depth of field captured using the highly functional built-in lighting unit. With these features, contamination, such as foreign particles, can be precisely and easily counted and measured even on targets having surface irregularities.

In detailed analysis mode, the stage moves automatically when the operator simply selects a contaminant on an image of the entire membrane filter, allowing the selected contaminant to be closely observed at high magnifications in the same image. This enables fast and easy identification of foreign particles. Additionally, the combination of the depth composition and 3D height measurement functions enables close observation and quantified 3D measurement even on targets having surface irregularities.

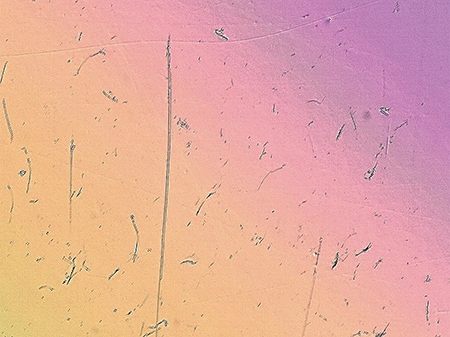

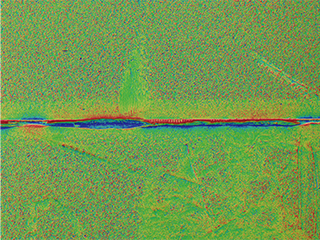

Observation of scratches on separators

The VHX Series high-resolution (HD) head can automatically switch between lenses to seamlessly change the magnification level from 20x to 6000x without replacing the lenses. The built-in lighting unit (motorised aperture) enables various observation methods such as brightfield, darkfield, polarised light, and differential interference contrast (DIC). This product can automatically support observation of any target.

For example, subtle scratches on separator surfaces can be visualised easily and quickly in a high-resolution 4K image captured using DIC.

Observation of peeled negative electrode materials

The VHX Series 4K digital microscope has a large depth of field, enabling observation with high-resolution 4K images focused throughout the entire observation field.

With the built-in lighting unit, this microscope also supports various observation conditions, enabling clear observation even if a target contains a mix of materials having different glossy surfaces.

Additionally, with the Multi-lighting function, image data is automatically captured with omnidirectional lighting at the press of a button. The observation image can be acquired by selecting the most suitable image for observation from the captured images. Because images other than the selected one are also stored, the target can be observed using other images captured under different lighting conditions. Additionally, the conditions used to capture a past image are reproduced and used for observing a different sample of the same type of target, which reduces human errors in observation and evaluation.

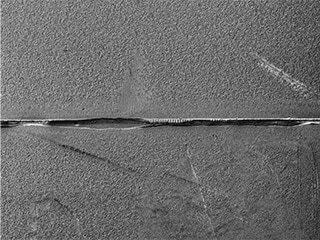

Observation of welded sections on battery cases

The quality of welding used to seal the lid or cover on square cases is very important to ensure the safety of lithium-ion batteries.

The VHX Series provides Optical Shadow Effect Mode, a new observation method that emphasises microscopic shapes. Subtle surface irregularities can be detected by analysing displacement (contrast) in an image captured with omnidirectional lighting, which makes it possible to obtain a clear observation image.

Colour information can be overlaid on this Optical Shadow Effect Mode image to visualise the surface irregularity information in an easy-to-understand manner by simultaneously representing the surface irregularity information and colour information and by displaying the surface irregularity information with different colours (colour mapping).

3D measurement of surface irregularities and profile measurement of the desired location can be performed using stored images even after observation. As such, there is no need to spend time on setting the same sample again, pinpointing the same location, and reproducing the observation conditions even when further analysis is required later.

As with PCs, spreadsheet software can be directly installed on the VHX Series. Captured observation images and measured values can automatically be output to a template, which significantly reduces the amount of time spent on making reports.

A 4K Microscope That Optimises Research, Development, Quality Assurance, and Quality Control of Secondary Batteries

The VHX Series 4K digital microscope provides clearness that can be obtained only in high-resolution 4K images and enables highly accurate 2D and 3D measurement and numeric data acquisition via counting and analysis of contamination, with simple operations. This microscope is a powerful tool to solve the problems in observation and inspection and greatly improve work efficiency using high-resolution images and quantitative numeric data.

Higher efficiency can be achieved for the series of operations of observation, analysis, evaluation, and report creation, reducing the time required for these operations. Higher efficiency can speed up workflows, which is a key factor for the secondary battery market in which fierce competition can be seen.

For additional info or inquiries about the VHX Series, click the buttons below.