PCB Failure Analysis and PCB Defect Analysis

More functional, smaller, and thinner terminals—such as smartphones—and devices require smaller and denser PCBs and electronic components. In the automotive industry, automatic brake and autonomous driving technologies have promoted computerised control. There is increasing demand for reliable PCBs and accurate and fast quality improvement through PCB failure analysis and PCB defect analysis.

This section introduces new examples of PCB failure analysis and PCB defect analysis using KEYENCE’s latest 4K Digital Microscope.

- Importance of PCB Failure Analysis

- Methods of PCB Failure Analysis and PCB Defect Analysis

- Latest Examples of Observation and Analysis of PCBs

- Improved Accuracy and Work Efficiency of PCB Failure Analysis and PCB Defect Analysis

Importance of PCB Failure Analysis

As smartphones, tablets, and wearable devices have become smaller, thinner, and more functional, PCBs and components continue to be even smaller, denser, and more layered. In the automotive industry, research and development of technologies such as automatic brakes and autonomous driving has promoted computerised control of important components. Such control then expects PCBs and electronic components to have high durability and reliability so as to withstand long-term stress caused by driving, accelerating, and stopping.

Terminals and devices now have an important role in various daily situations, and cars require a high degree of safety. Any failures and defects of important components that are computerised in such products can lead to serious trouble or accidents.

To evaluate the durability and reliability of PCBs and electronic components, reliability evaluation tests, including acceleration tests, have become increasingly important. In addition to such tests conducted on products, from the point of view of market product quality assurance, identifying causes and improving quality through PCB failure analysis and PCB defect analysis using microscopes are now deemed more important than ever, and thus require higher accuracy.

This section explains methods of PCB failure analysis and PCB defect analysis for issues such as inappropriate mounting and electronic component defects caused during manufacturing or after shipping.

Methods of PCB Failure Analysis and PCB Defect Analysis

The following methods are available for PCB failure analysis and PCB defect analysis.

- Identifying failure locations

- Failure locations are identified by, for example, lock-in thermal emission (LIT), which reproduces the failure electrically to identify heated areas caused by short-circuits or leaks of electronic components and units.

- Understanding failure locations

- To correctly understand the physical properties of microscopic structures, they are observed using a transmission X-ray microscope, CT scanner, electron probe micro analyser (EPMA), or other instruments.

- Observing and analysing defective areas (defect analysis)

- To identify specific causes, defects are closely analysed through cross-section observation of defective areas, which uses tools such as microscopes, scanning electron microscopes (SEMs), focused ion beam (FIB) microscopes, and EPMAs; or plane observation, which is applied to polished surfaces and opened resin packages.

Latest Examples of Observation and Analysis of PCBs

In the PCB failure analysis and PCB defect analysis introduced in the previous section, the accuracy of the observation and analysis of defective areas is particularly important. To identify causes of failures found in products on the market or through reliability evaluation tests, analysis and evaluation need to be accurate and quick.

Microscopes are often used to inspect the appearances of defective areas in such analysis and evaluation.

KEYENCE’s VHX Series high-definition 4K Digital Microscope uses a high-resolution lens and cutting-edge technology such as a 4K CMOS image sensor, enabling accurate observation and analysis of defective areas with clear 4K images. The VHX Series also supports 2D and 3D measurements with easy operation using high-resolution magnified images. Such measurements contribute to highly accurate, quick performance of the series of tasks required for analysis.

This section introduces the latest examples of observation and analysis using the VHX Series.

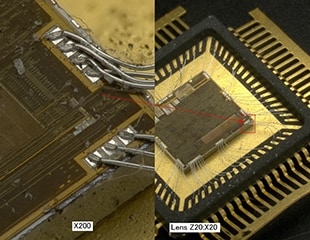

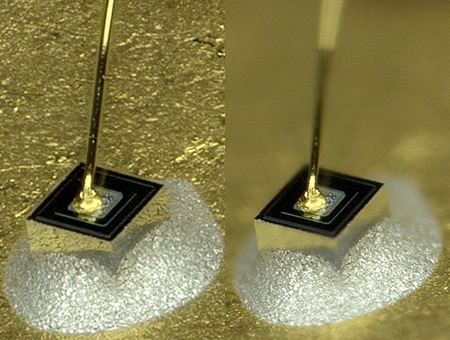

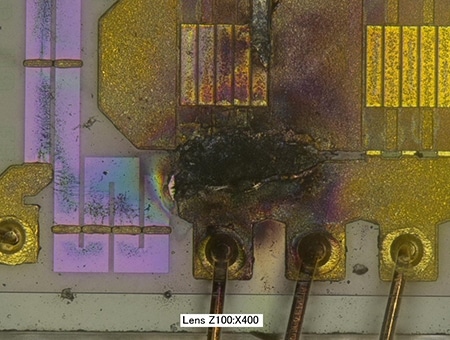

Observation and analysis of wire bonding

The VHX Series 4K Digital Microscope has a free-angle observation system, which enables tilted observation freely from any angle; uniform lighting, which is achieved with the highly functional built-in light; a glare removal function, which reduces glare from reflective surfaces; and real-time depth composition, which brings the entire target into focus. All these features allow users to observe and analyse three-dimensional wire bonding correctly on fully focused, clear high resolution images even at high magnification.

(left: 200x/right: 20x)

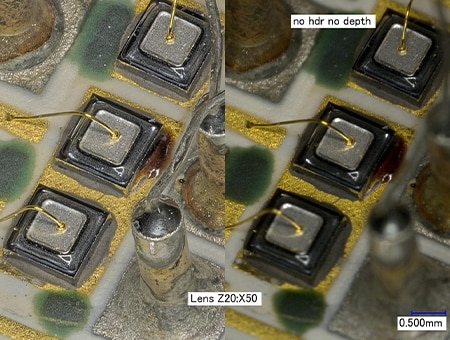

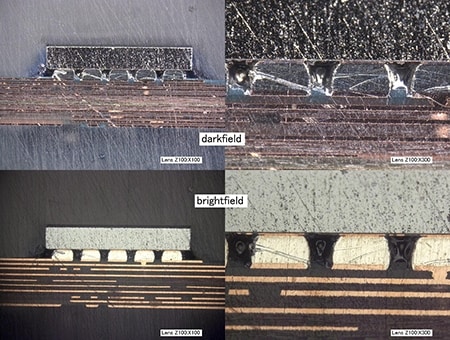

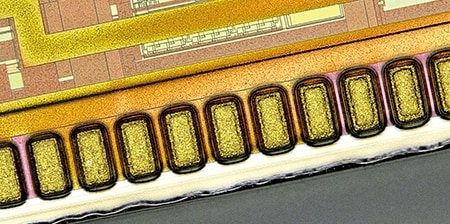

Observation and analysis of cross sections and surfaces of semiconductor packages

The VHX Series 4K Digital Microscope is equipped with versatile lighting, including darkfield, brightfield, differential interference contrast (DIC), and polarised lighting. This versatile lighting allows users to observe the characteristics of glues and pastes that are used for semiconductor packaging and the shapes of materials.

Even if the target cross section of a resin-embedded sample has irregularities due to inappropriate cutting or polishing, the surface can be displayed in three dimensions using a limited number of images, allowing users to capture a fully focused image even at high magnification.

bottom: brightfield lighting (100x and 300x)

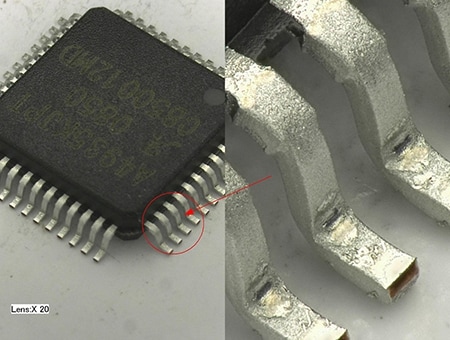

With the free-angle observation system of the VHX Series, package surfaces and pins can be observed at high magnification from any angle. A deep depth of field enables quick and highly accurate analysis with fully focused images, eliminating the need for troublesome adjustments.

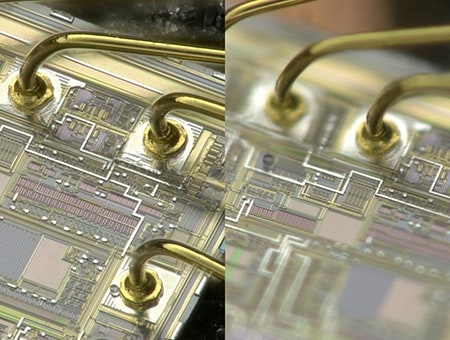

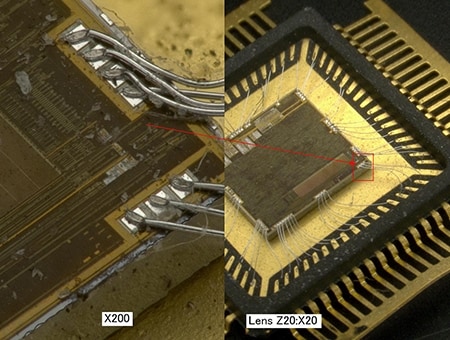

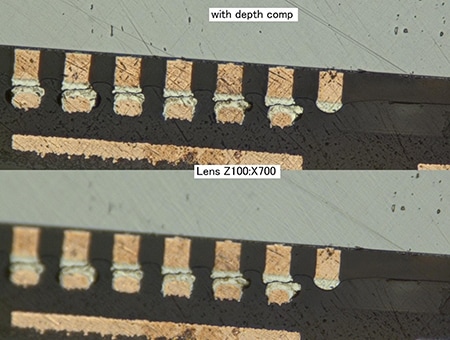

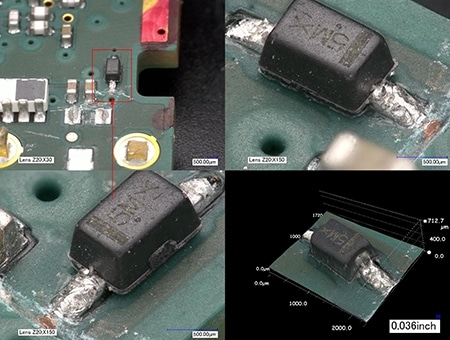

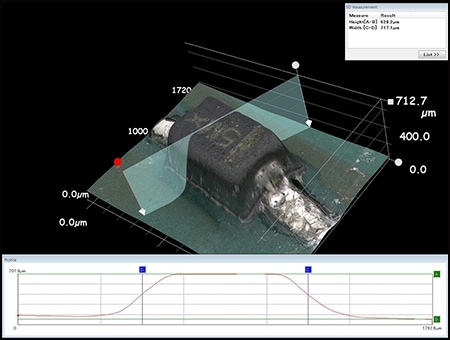

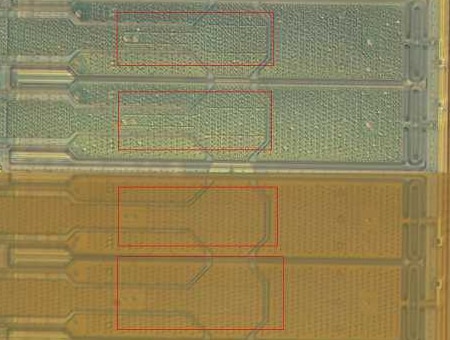

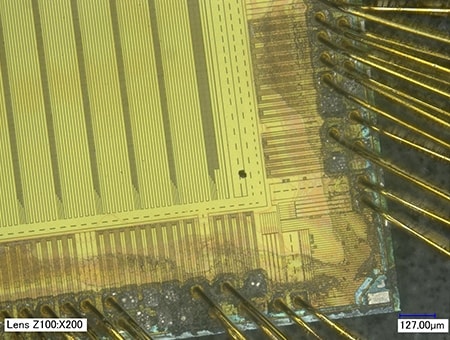

Observation, measurement, and analysis of PCBs

The high-resolution lens and motorised revolver of the VHX Series 4K Digital Microscope enable a seamless zoom function that automatically switches between lenses from 20x to 6000x magnification. This function allows users to perform zooming and observation with intuitive operations. With the free-angle observation system, fully focused, high-resolution images can be captured even in tilted observation at high magnification. Therefore, three-dimensional mounting components can be observed and analysed clearly. Images at different magnifications can be displayed side by side using the split-screen function, allowing users to always track the defective mounting area to analyse even in the case of dense PCBs.

Furthermore, submicron-order 3D shape and profile measurements can be performed directly on a high-resolution image using the height information, allowing users to complete quantitative analysis and evaluation with a single unit.

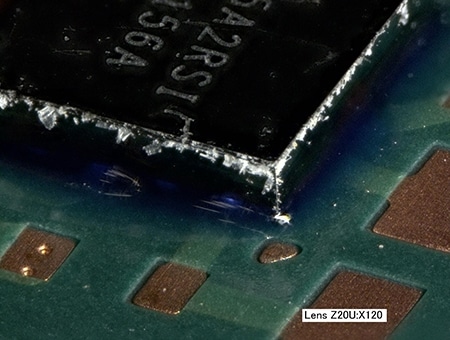

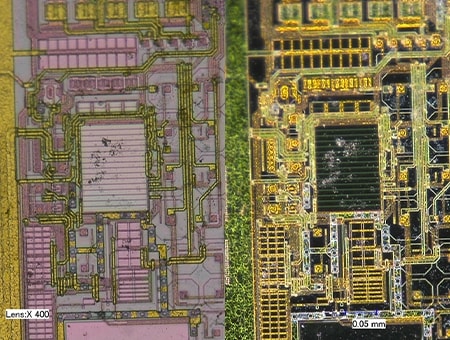

Final appearance inspection of IC chips

The VHX Series 4K Digital Microscope supports high magnifications up to 6000x, thereby enabling the capturing of high-resolution 4K images even at high magnification. With depth composition and the HDR function, targets having irregular surfaces can be fully focused under various lighting conditions, thereby allowing users to capture even subtle scratches on IC chip circuit patterns.

In addition to PCB failure analysis and PCB defect analysis, quick and accurate analyses and evaluations can be performed in the final appearance inspections carried out at manufacturing sites.

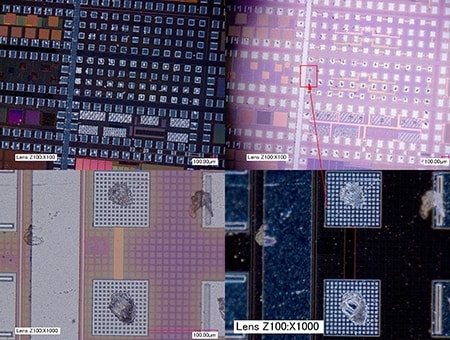

of a failure location (up to 1000x)

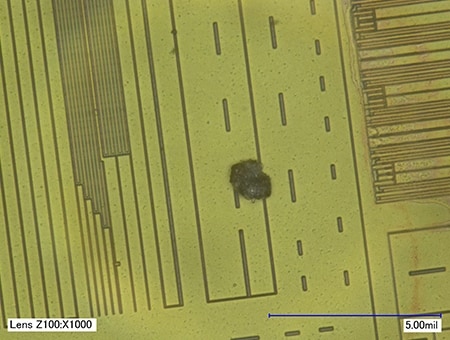

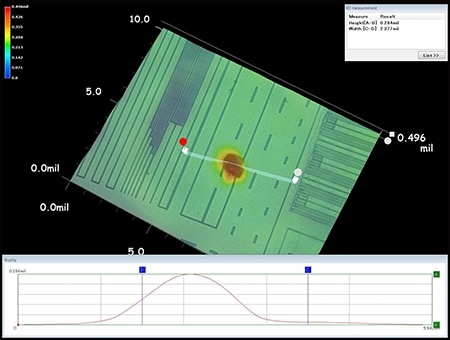

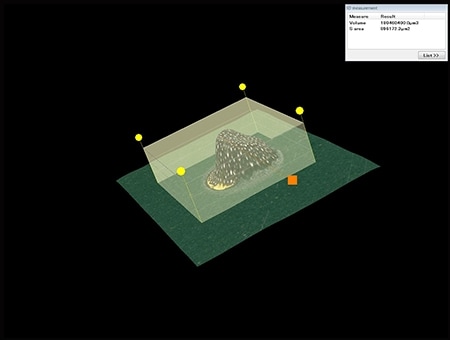

Inspection and analysis of foreign particles mixed into IC chips

Foreign particles mixed in circuits can cause short-circuits, resulting in component failures and defects.

The VHX Series 4K Digital Microscope captures clear images of foreign particles at high magnification. 3D imaging, which can be performed with a limited number of images, allows users to discriminate foreign particles from irregularities on the circuit surface.

Furthermore, the VHX Series enables 3D shape and profile measurements of foreign particles using the height information from 3D imaging. A single unit makes it possible to complete all tasks quickly from quantitative evaluation of the size, structure, and volume of a foreign particle to report creation using captured images and measured values.

Improved Accuracy and Work Efficiency of PCB Failure Analysis and PCB Defect Analysis

With the VHX Series 4K Digital Microscope, which enables 2D and 3D measurements as well as observation and analysis with clear high resolution images with a single unit, dramatically changes the accuracy and work efficiency of PCB failure analysis and PCB defect analysis, regardless of the three-dimensional structures of PCBs.

Advanced analysis and quantitative evaluation can be performed with simple operations, allowing anyone, regardless of skill level, to obtain the same results.

In addition to the functions introduced here, the VHX Series is equipped with many more functions, supporting analysis of various failures and defects that occur in various types of targets.

For details on the VHX Series, click the button shown below to download the catalogue. For inquiries, click the other button shown below to contact KEYENCE.