Tilted Observation and 3D Measurement of Microneedles and Their Moulds

Microneedles are not just used in the field of medicine but also widely in the field of cosmetics to easily and painlessly administer liquid medicine to the epidermis. There is a type whose needle dissolves inside the human body, and this type is gaining attention as a new Drug Delivery System (DDS). These advantages have increased the demand for microneedles, making high quality and reliability necessary in their mass production. This section introduces basic microneedle knowledge such as their types and applications as well as an example of the observation of the moulds used in production and an example of non-contact measurement of the 3D shapes and dimensions of microneedles.

- What Is a Microneedle?

- Microneedle Types and Applications

- Examples of Tilted Observation and 3D Measurement of Microneedles and Their Moulds

- A 4K Digital Microscope That Strongly Supports the Quality Maintenance and Research and Development of Microneedles

What Is a Microneedle?

Microneedles are microscopic needles with diameters and lengths both less than 1 mm. Generally, a large number of microneedles are arranged perpendicular to the sheet in a grid with each needle close to those around it. In dermal administration, the microscopic needles pierce the skin, passing through the stratum corneum on the skin surface, allowing for direct administration to the epidermis, which differs from general ointments and medicinal patches.

Microneedle applications

They are used not just for medication such as anesthetisation, insulin, vaccines, and hyaluronic acid but also widely in the administration of solutions for non-medicinal cosmetic purposes.

Microneedle advantages

Administration to multiple points at a shallow depth on the skin (the epidermis) is possible, differing from the use of a general hypodermic needle, which administers the medicine to a single point in the dermis or lower in the hypodermis. A corresponding advantage is that the solution can be administered easily and painlessly because the needles do not reach the dermis, which has many pain points.

Microneedle Types and Applications

Conventionally, the popular material for needles has been metal, but the use of microneedles produced through various methods; having various shapes; and made of various materials such as biomass plastic, biodegradable plastic, and water-soluble polymers is becoming commonplace. Typical microneedle classifications are as follows.

- Non-dissolving (biodegradable) microneedles

- These microneedles are made of polyglycolic acid (PGA) and polylactic acid (PLA), polymers used in medical devices, and the solution is applied to the tips of the needles. This type is expensive but is used as the optimal microneedle for solutions and vaccines that must be administered in extremely small amounts. Typical applications include the administration of influenza vaccines and therapeutic drugs for hepatitis C, diabetes, and osteoporosis.

- Dissolving microneedles

- These microneedles use microscopic needles made from water-soluble polymers (such as hyaluronic acid), peptides, and protein drugs. In most cases, a sheet of microneedles is affixed to the skin, whose moisture then dissolves the needles, administering the solution to the epidermis. One typical application is the administration of local anesthetics, but the use of these microneedles for cosmetic purposes such as administering hair growth agents and improving blemishes and wrinkles has become more and more common in recent years.

Examples of Tilted Observation and 3D Measurement of Microneedles and Their Moulds

Microneedle production methods vary depending on their type and material. Because these needles require high accuracy, when forming them with moulds, it is important to check the moulds for wear and flaws after a certain number of shots in order to prevent defects and to identify the causes of defects that do occur.

In addition to moulds, microneedle production methods also include creating needles on sheets with a dispenser, laser processing, and 3D printing. There are diverse methods, and new technologies are being researched actively. Regardless of how microneedles are produced, the observation, measurement, and evaluation of the 3D shapes of the needles are vital in the quality management, quality assurance, and research and development of microneedles.

However, it is very difficult to observe the precisely arranged microscopic needles and the moulds and to measure the 3D shapes and to perform 3D measurements of all the needles with optical microscopes and contact measurement systems.

KEYENCE has continued developing new digital microscopes for more than 30 years, putting to use the testimonials of on-site operators in order to solve their problems. The VHX Series 4K digital microscope is a microscope resulting from our latest technologies and the know-how we have accumulated over all these years.

Read on for examples of easily using the VHX Series for tilted observation of microneedle moulds and for 3D imaging and measurement of microneedles.

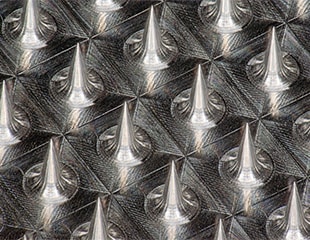

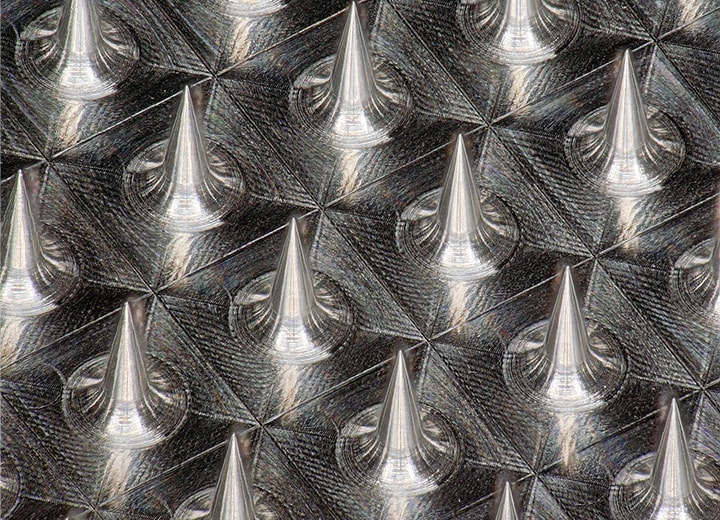

Tilted observation of a microneedle mould

Moulding is one typical microneedle production method. Mould management is vital in ensuring that each and every one of the many arranged microscopic needles is produced free of problems and defects.

However, moulds have precise and complicated three-dimensional shapes, so with optical microscopes it is necessary to use a jig to secure and tilt these small targets on the stage. It is also necessary to take a lot of time and effort to determine the lighting conditions due to the diffuse reflections of light characteristic to the metal material.

The VHX Series 4K digital microscope uses a free-angle observation system with XYZ motorised stage to enable tilted observation with easy field-of-view alignment, rotation, and oblique axis motion. Eucentric design ensures that the target stays centred in the field of view even if the lens is tilted or rotated, resulting in tilted observation that is both easy and smooth.

The VHX Series is equipped with an optical system and a 4K CMOS image sensor that combine high resolution with a large depth of field and with an observation system that provides access to diverse functions with simple operations. The large depth of field allows entire three-dimensional targets to be brought into focus. In addition, the depth composition function can be used to easily capture images that are fully focused throughout the entire field of view even when observing three-dimensional targets at high magnifications. Of course, this depth composition function can also be used during tilted observation.

Furthermore, this product is equipped with the Multi-lighting function, which automatically acquires the data of multiple images captured with omnidirectional lighting at the press of a button. Observation can be started immediately just by selecting the image that matches the purpose, which greatly reduces the condition determination time required until now.

The high performance and diverse functions described above allow for easy and fast tilted observation with high-accuracy 4K images even when observing the 3D shapes of microneedle moulds.

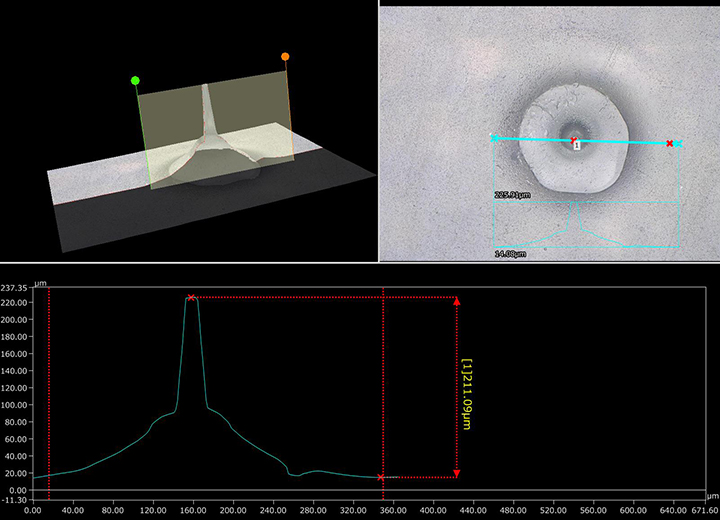

3D measurement of microneedles

The VHX Series 4K digital microscope allows not just for observation with high-resolution 4K images but for 3D measurement using these same images.

This product quickly composes the image from multiple images with varying focus positions, allowing it to display 3D images that even capture textures and surface roughness. The result is that the 3D image displayed on the screen can be rotated to any angle for observation without having to move the target on the stage or change the angle of the lens.

Furthermore, 3D measurements can be performed from the high-accuracy 3D information that has been acquired, and profile measurements can be performed simply by selecting a cross section with the mouse while watching the screen. Sub-micrometre level measured values can be acquired for 3D measurements, cross-section shapes, and surface irregularities of the delicate microscopic needles of microneedles in a non-destructive, non-contact manner.

A 4K Digital Microscope That Strongly Supports the Quality Maintenance and Research and Development of Microneedles

The VHX Series 4K digital microscope allows for fast observation, 2D/3D measurement, and profile measurement with clear 4K images and simple operations even if the target has microscopic shapes like microneedles and the moulds used to produce them.

Equipped with many other functions that optimise observation and analysis and are accessible with simple operations, this one device can even support automatic report generation.

With its high performance, functionality, and usability, the VHX Series can greatly optimise microneedle production work, which requires high reliability and safety and is extremely competitive in the field of research and development.

For additional info or inquiries about the VHX Series, click the buttons below.