Key inspection points

The vision system is used for traceability by reading 2D codes inscribed on parts. Flexible reading can be performed even if the tones are inverted due to the surface conditions of the part or the influence of reflections.

Check for information (such as text or 1D and 2D barcodes) on a target, and output the results as text strings.

Fuel pump 2D code reading

The vision system is used for traceability by reading 2D codes inscribed on parts. Flexible reading can be performed even if the tones are inverted due to the surface conditions of the part or the influence of reflections.

Intuitive Vision System

CV-X Series

"Best by date" printing inspection

Inspections are performed for print defects such as incorrect characters and character defects. Identification data is recorded and linked with the inspection images making it possible to trace unexpected trouble back to specific production dates.

Intuitive Vision System

CV-X Series

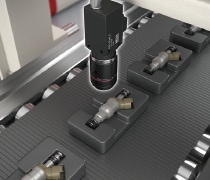

Injector stock number OCR

The OCR tool is used to read the stock numbers marked on injectors.

Even if the shape or marking position on the injector varies between different models, it is possible to accurately read the marking details, which prevents the mixing of different models.

Intuitive Vision System

CV-X Series

Date, lot code, and barcode inspections

In the medical industry, the need to track individual packages throughout the production process continues to increase. With machine vision, it is possible to perform a variety of inspections - such as character, barcode, and label inspections - with a single device.

Intuitive Vision System

CV-X Series