ITF and Standard Distribution Code

About 100 types of barcodes are available in the world. The following is an introduction to ITF barcodes.

ITF

ITF is the abbreviation for "Interleaved Two of Five". It is widely used as the standard distribution code printed on corrugated cardboard boxes.

There are several types called "2 of 5" as shown below. All of them represent one character using the same composition consisting of 2 wide bars (spaces) out of 5 bars (spaces). Although their composition is similar, the code is completely different.

ITF Composition

- ITF uses 5 bars (spaces) to represent one character. Since the two bars out of the five are wide, it is named "2 of 5".

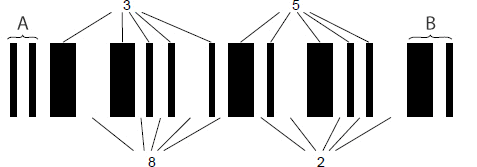

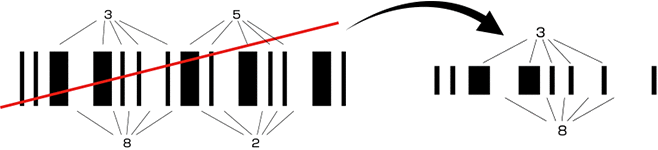

- In ITF, characters represented by bars are interleaved with characters represented by spaces, as shown below.

- A

- Start code bars

- B

- Stop code bars

| Character | Bar pattern |

|---|---|

| START |  |

| 2 |  |

| 3 |  |

| 5 |  |

| 8 |  |

| STOP |  |

- The first character is represented by 5 bars and the second one by 5 spaces. Therefore, ITF has always even digits. ("ITF of 5 digits" unavailable)

- ITF has high-density composition, because both bars and spaces have information.

- No start/stop character is used, but bar patterns representing start and stop are used.

ITF Character Composition

ITF is composed using the characters in the following table. Characters that can be represented are numbers only (0 to 9).

| Character | Bar pattern |

|---|---|

| START |  |

| 0 |  |

| 1 |  |

| 2 |  |

| 3 |  |

| 4 |  |

| 5 |  |

| 6 |  |

| 7 |  |

| 8 |  |

| 9 |  |

| STOP |  |

ITF Features

As ITF is the barcode with very high data density, it offers the following features:

- The label size can be smaller than those of other codes with the same digits.

It is effective to print barcodes in small spaces. - More data can be contained compared with other codes, if the label size is same. (Number of digits can be increased.)

- Wider bar width is possible, if the label size and the number of digits are same.

If the bar width is wider, it is easy for the barcode reader to read. The reading with long distance can also be performed.

Comparison of barcode length

The following figures show a comparison of the barcode length of each barcode type, when the same narrow bar width and the same amount of information are used. It is obvious that the ITF is the shortest.

(Comparison is based on the binary level barcodes)

-

ITF -

CODE39 -

Codabar

ITF Applications

- ITF is used for more information required in a small space.

- It is used for the standard distribution code to be printed on corrugated cardboard boxes. (The details are explained here)

Disadvantages of ITF

Although ITF has many advantages, it also has the disadvantage of possible "skip reading" due to its composition. Skip reading means that the barcode representing "3852" is incorrectly read as "38" with some digits being skipped.

Standard Distribution Code

The standard distribution code based on ITF is explained in details.

What Is Standard Distribution Code?

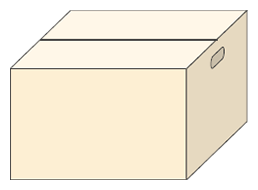

Standard distribution code is a barcode mainly marked on a corrugated cardboard box and standardised for the distribution system. The following section describes how the standard distribution code was introduced.

Just-in-time Needs

Retail stores such as supermarkets aim to reduce the inventory in order to keep as wide floor space as possible. To meet this requirement, manufactures and whole sellers have to deliver the ordered goods without fail in the required quantity at the required time. This is called the just-in-time system (JIT). This brings the following situation.

(1) Diversification of packaging

Retailers place orders in various unit quantities like 120 pieces or 10 pieces. Therefore, various package sizes are developed to meet such requirements as 120 pieces or 10 pieces.

(2) Truck transportation as main distribution means

Since the quantity for the delivery at a time has decreased and the frequency of the delivery has increased, truck transportation plays the main part of the distribution.

Under the current traffic conditions, it is however not allowed to park a truck for a long time for loading and unloading. Therefore, packages must be prepared (picked) so that they can be loaded onto the truck that is expected to arrive at the specified time. If every order slip is checked at that time, it takes too much time to complete the loading on the truck in time.

Creation of Standard Distribution Code

The standard distribution code was created to meet the trend of distribution diversification. The standard distribution code indicates the contents of EAN code of the products contained in the package and the packaging data (the product quantity in the package). When the standard distribution code is read by the barcode reader, the item and quantity of the product is known instantly. This allows many things in the distribution system to be rationalised, such as "picking", "assortment", "checking product", "stock control" and "stock taking".

Composition of Standard Distribution Code

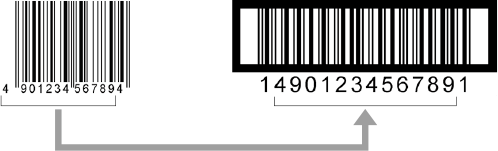

The standard distribution code consists of the EAN code of the product packaged and the prefixed distribution identification code.

- JAN code

- Standard distribution code

Data composition is as follows:

- A

- Distribution identification code (1 digit)

- B

- Country code (2 digits)

- C

- Manufacturer code (5 digits)

- D

- Product item code (5 digits)

- E

- Check digit (1 digit)

Assigning Distribution Identification Code

The distribution identification code represents the quantity and the contents of the products mixed in the package, using 1 digit. For the indication of the quantity, it does not represent the actual quantity of the product in the package, and the code corresponding to the quantity is defined by users.

| Distribution identification code |

Description |

|---|---|

| 0 | Package containing products mixed |

| 1 to 7 | Quantity of the same product in the package |

| 8 | Reserved |

| 9 | Add-on version added |

See here for add-on version

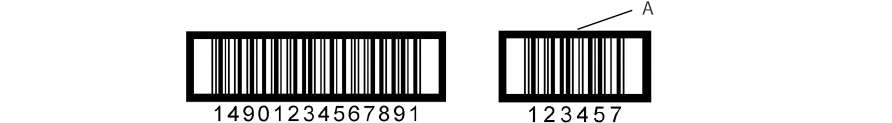

- A

- EAN code

- B

- 6 pieces packaged

- C

- 12 pieces packaged

- D

- Standard distribution code

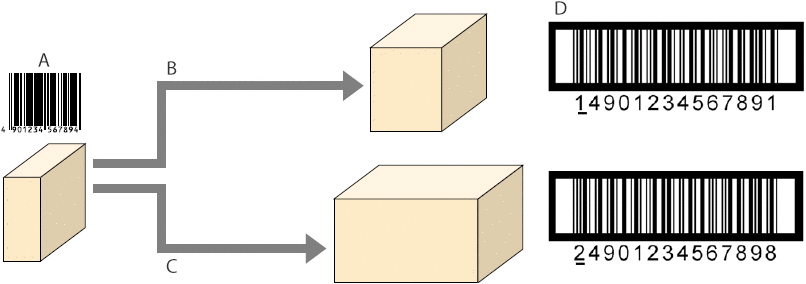

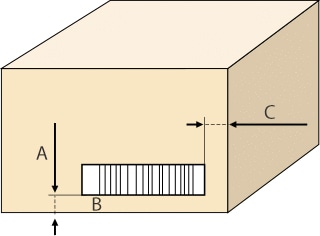

Standard Size of Standard Distribution Code

The size of the standard distribution code can be enlarged or reduced within the magnification range of 0.25 to 1.2 based on the standard narrow bar width of 1 mm (magnification ratio: 1). (Magnification of 0.625 to 1.2 is applied for export.) The length of barcode with each magnification is as follows. (The barcode length includes the quiet zones.)

- A

- Bar code length

- A

- 32 ±3 mm

- B

- 149

- C

- 19 mm or more

| Magnification | Barcode length |

|---|---|

| 1.2 | 171 mm |

| 1.0 | 143 mm |

| 0.8 | 114 mm |

| 0.625 | 89 mm |

| 0.40 | 57 mm |

| 0.25 | 36 mm |

Why Is ITF Used?

ITF allows wider narrow bar width compared with other codes, if the label size and the number of digits are same. Therefore, even the printers with poor print quality can print the ITF code. Moreover, wider narrow bar width allows the barcode to be read from a long distance.

What Is Add-on Version?

The add-on version is the distribution code added after the standard version of the standard distribution code. It is used for products such as ham and sausages whose prices vary according to the weight of each individual package. The add-on version consists of five digits representing the measured value and the check digit with 1 digit. If a decimal point is necessary, it shall be placed between the third and fourth digits. Instead of add-on version, "GS1-128" based on CODE 128 is currently used as a code to represent measured values.

- A

- Add-on version

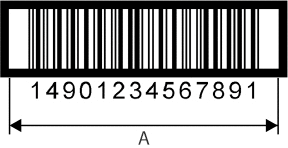

Bearer Bar

Barcodes are printed on corrugated cardboard boxes using flexographic printing (the printing method using a resin or rubber relief press). Since the surface of corrugated cardboard is not completely flat, the printing pressure of the flexographic press is not applied evenly. This may cause a distorted barcode. A bearer barcode is used to prevent the direct printing pressure from being concentrated on the barcode and to keep the printing pressure even.

- A

- Bearer bar