FAQ: Troubleshooting Problems Reading Codes

This section contains questions related to the causes and solutions when a barcode reader has trouble reading a barcode or 2D code.

Problems Reading Barcodes

- Q.01Why is there a white line on the barcode when it is printed by a thermal printer?

-

- A.01The thermal printing head may need to be replaced.

-

NORMAL PRINTING

MISSING PRINT The figure on the right shows that the print is missing a line from the barcode through the number 1.

This is referred to as “missing dots”, which can cause a misread.

- Q.02The barcode reader was installed based on a recommended distance, but it doesn’t read the barcodes.

-

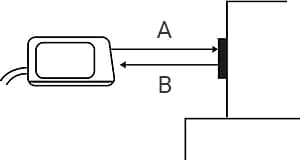

- A.02The barcode reader might be installed at a perpendicular angle to the target.

-

- A

- Laser beam

- B

- SPECULAR BEAM

A barcode reader installed at a perpendicular angle to the barcode receives an intense reflection (specular beam) which results in a misread. This is why the barcode reader does not function properly.

- Q.03Why are glossy barcodes difficult to read?

-

- A.03Because glossy barcodes do not diffuse the reflected beam well.

-

Laminated barcode

Metallic or silver background A laser beam reflects specularly off of a barcode with a glossy surface. It is difficult for the barcode reader to scan because such barcodes barely diffuse the reflection.

- Q.04The barcode reader can’t scan barcode labels placed on metal surfaces. Is the barcode reader affected by the reflection from the metal?

-

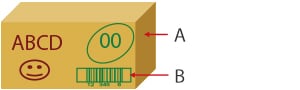

- A.04The quiet zone on the barcode label may be too narrow.

-

- A

- Laser beam

- B

- Metal surface

Since metal does not diffuse the beam, the barcode reader scans it as black. Because of this, the barcode’s quiet zone is too narrow (as shown here) and it is unreadable.

- Q.05The barcode reader could read stably during testing, but reading has become unstable in normal operations.

-

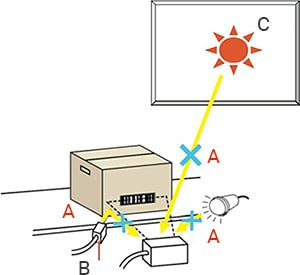

- A.05Ambient light may be the cause of the problem.

-

- A

- Ambient light

- B

- Photoelectronic sensor

- C

- Sunlight

Sunlight may cause unstable reading when directed towards the reader.

- Q.06Why is a dot matrix printer not suitable to print UPC/EAN and CODE128?

-

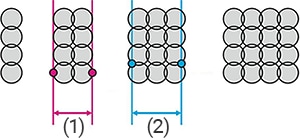

- A.06UPC/EAN and CODE128 have four types of bar and space widths.

-

When printing a one-dot narrow bar. Due to the nature of Dot Matrix printing, the width of each bar will vary throughout the length of the bar. Some positions will be wider, (1), while others will be narrower, (2). Such widths can be difficult to differentiate between, which may cause the barcode to be unreadable.

- Q.07Why is my barcode reader unstable when reading barcodes printed on cardboard?

-

- A.07Cardboard’s inconsistency may cause unstable readings.

-

- A

- Background

- B

- Barcode

A barcode is made up of bars (printing) and spaces (background). Both the print and the background can change due to inconsistent surface conditions that can cause unstable readings.

Problems Reading 2D Codes

- Q.01The code was printed correctly. Why doesn’t it read?

-

- A.01The quiet zone may be too narrow.

-

Narrow quiet zone: The only white area is in the 2D code.

Influenced by the border: The code is surrounded by a black border.

No quiet zone: The code extends to the edge of the label.

- Q.02Why is it unable to read when only part of the code is damaged?

-

- A.02Alignment pattern may be damaged.

-

DataMatrix codes are read by first locating the L-shaped frame called the alignment pattern. Due to this, the code cannot be read if the alignment pattern is damaged.

- Q.03The modules and spaces are different colours and the printing quality is good. Why doesn’t the scanner read the 2D code?

-

- A.03It may be difficult to read due to the colour contrast.

-

Black Pattern

on a Blue Background

Black Pattern

on a Green Background

Red Pattern

on a White Background2D code readers perform scans by looking at the contrast between the print pattern and the background. Therefore, scanning cannot be done if it is difficult to distinguish enough contrast.

- Q.04I set the reader to the recommended distance. Why is it completely unable to read codes?

-

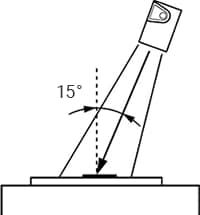

- A.04The reader may not be installed at a proper angle, or a reader with polarising filter may be needed.

-

Example of installation at an angle

Some 2D code readers are designed to be installed at an inclined angle, while others should be at a perpendicular angle to the target. If not properly installed, stable scanning cannot be performed.

- Q.05The code reader could read stably during testing, but reading has become unstable in normal operations.

-

- A.05Ambient light may be the cause of the problem.

-

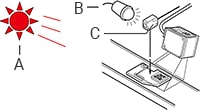

- A

- Sunlight

- B

- Light

- C

- Photoelectronic sensor

2D code readers use lighting like a camera to perform scanning. Sometimes, when too much ambient light reaches the target or reader, the brightness becomes unequal and results in unstable scanning.