Non-contact Type

A non-contact type measuring instrument uses light in place of the stylus of a contact-type measuring instrument. These instruments come in multiple types, such as confocal types and white light interference types, and vary depending on the principle used. Also, there is a variety of contact-type detectors such as those that have been changed into non-contact types by replacing their probes with optical sensors and microscope types. This section will use KEYENCE's 3D laser scanning microscope VK-X Series as an example to explain the confocal type.

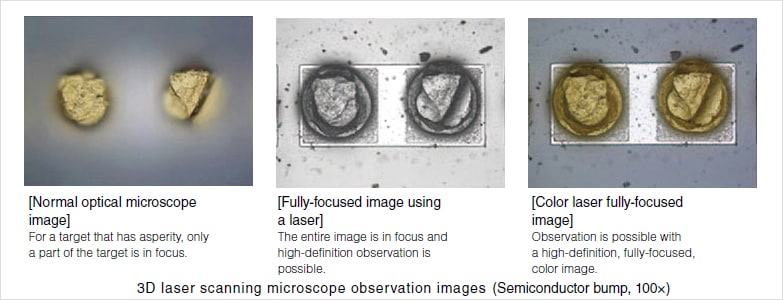

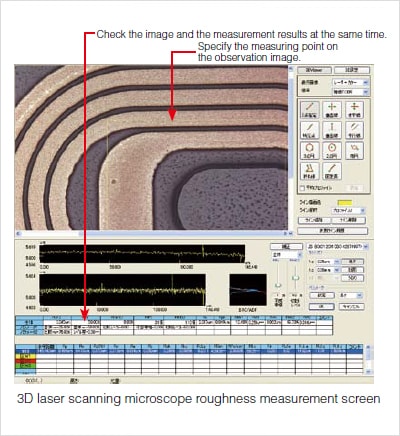

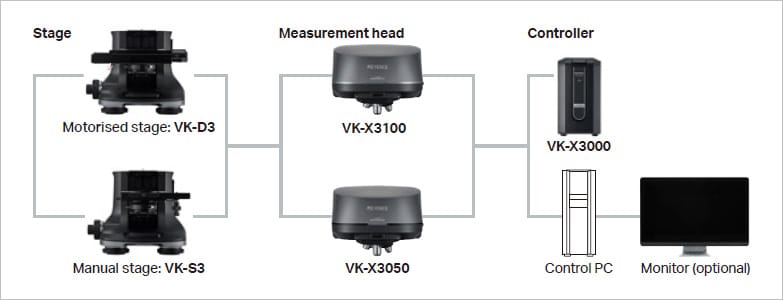

A 3D laser scanning microscope uses the confocal principle to measure the asperity of the target's surface. It uses a laser as the light source. The system is configured as shown in the figure on the right. Set the target on the XY stage of the measurement unit, and then perform the measurement.

With the KEYENCE 3D laser scanning microscope VK-X Series, an X-Y scanner is embedded in the measurement unit. The laser, which is the light source, scans across the surface of the target in the X and Y directions in order to acquire the surface data.

The principles are explained below.

3D laser scanning microscope measurement principles

- 1. The laser beam emitted from the laser light source scans the target surface.

- 2. The laser light reflected from the target surface passes through the half mirror and enters the light-receiving element. At this point, the intensity of the received reflection and the height position of the lens are recorded in memory. The laser microscope acquires 1024 data points in the X direction and 768 data points in the Y direction. The reflected light intensity and the lens height position are recorded in memory for each of the 1024 × 768 = 786432 points.

- 3. When the scan of one surface finishes, the objective lens moves in the Z direction by the specified pitch.

- 4. The same surface scan is performed again for the surface that the objective lens has moved to, and then the laser's reflected light intensity is checked over 1024 × 768 points. The reflected light intensity of each pixel is compared with the reflected light intensity recorded in memory as "v". If the new reflected light intensity is higher, the reflected light intensity data and lens height position data are overwritten.

- 5. The operations of steps (2) to (4) are repeated for the specified Z distance.

- 6. Finally, for each of the 1024 × 768 pixels, the reflected light intensity and lens height position are recorded in memory at the time when the strongest laser light reflection was received.

- 7. For optical microscopes, the WD (Working Distance: the distance from the objective lens to the target) when the objective lens is in focus is constant. If it is assumed that the image is in focus when the reflected light intensity is at maximum, it is possible to obtain 3D data in the observation area (1024 × 768 pixels) of the microscope by stitching together the lens height positions from the different times that the image was in focus, that is, when the reflected light intensity was at its maximum.

3D laser scanning microscope measurement accuracy

The ability to accurately read the peak value of the reflected light intensity has a large effect on the measurement accuracy of confocal measurement systems. There are many ways to construct a confocal optical system.

The pinhole confocal method used by KEYENCE's 3D laser scanning microscopes is explained below.

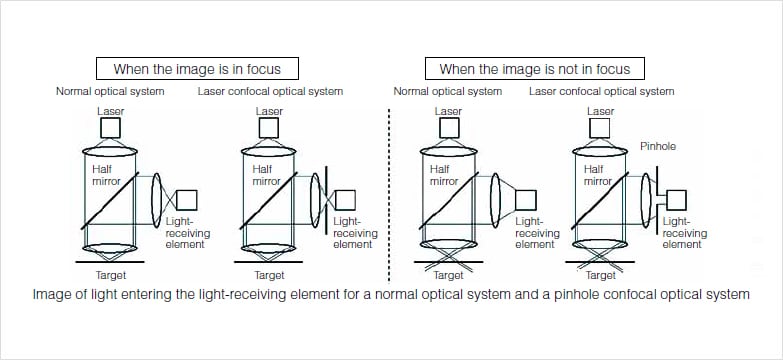

In the pinhole confocal method, a pinhole is placed in front of the light-receiving element. The pinhole has a diameter of just tens of micrometres and has the role of blocking the reflected light when the image is not in focus.

When the image is in focus in the following figure, the reflected light is received by the light-receiving element in both the normal optical system and the laser confocal optical system. Looking at the part of the figure where the image is not in focus, the reflected light (out-of-focus light) enters the light-receiving element for the normal optical system but is blocked by the pinhole in the laser confocal optical system. In other words, the structure is such that the reflected light only enters the light-receiving element when the image is in focus, and this structure is used to construct the confocal optical system.

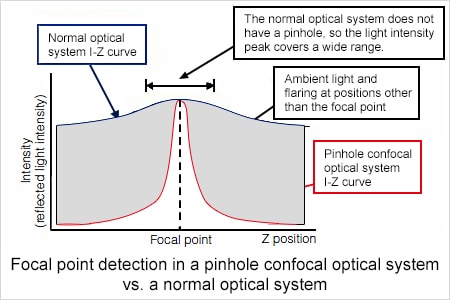

The pinhole's affect on the received light is illustrated in the figure to the right. With the confocal optical system, the reflected light intensity peaks at the focal point. On the other hand, the normal optical system results in a gently sloping curve.

The lack of a peak at the focal point makes it difficult to detect when the target is in focus.

Laser XY-direction resolution

For non-contact types, the light beam spot corresponds to the stylus of contact types. Non-contact types do not directly touch the target, which makes them different from contact types. Therefore, non-contact types do not have the disadvantages of stylus wear and the risk of scratching the target. However, the size of the beam spot diameter is important in accurately measuring the profile of the target. Generally, the smaller the beam spot diameter, the smaller the features that can be measured.

Laser microscopes use lasers for their light sources, which makes it possible to create an extremely small beam spot.

When using a 150× (N.A. = 0.95) objective lens, the VK-X Series, which uses a violet laser for its laser light source, achieves a resolution of 0.13 μm for the planar spatial resolution. A laser microscope can measure asperity with a very small width, which cannot be measured with contact types.