Surface roughness pictorial representation method

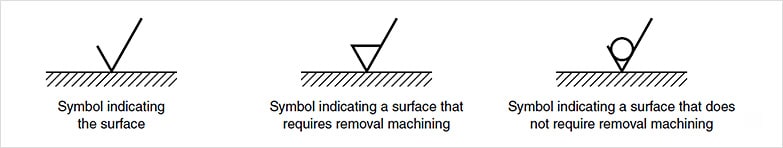

Symbols that indicate the surface texture of machine parts and structural parts are used in industrial diagrams.

The pictorial representation method using these symbols is defined in ISO 1302:2002.

This section will explain how to write these symbols to indicate surface textures.

Terminology explanation

| Surface texture | This is a general term for factors such as the roughness, necessity of removal machining, crease direction, and waviness of the surface of machine parts and structural parts. |

|---|---|

| Removal machining | This refers to the removal of surface layers from parts by way of machining or similar methods. |

| Crease direction | This is the direction of clear creases that are formed during removal machining. |

Symbols that indicate the target surface and the position of these symbols

When pictorially representing the surface texture, the symbol that indicates the target surface is expressed with two lines having different lengths with an angle of 60° between them.

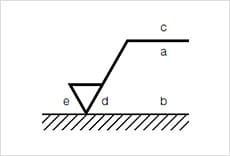

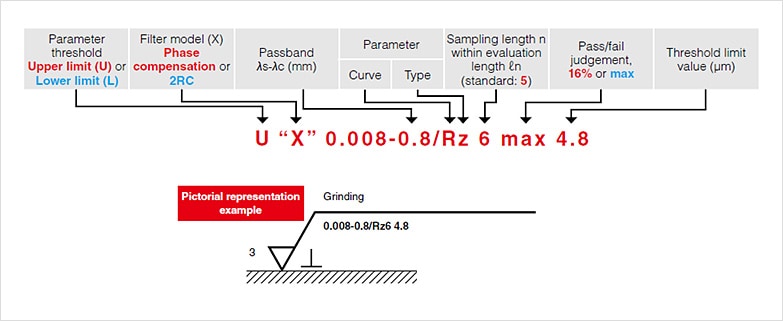

This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol, and surface waviness on the surface indication symbol as shown below.

- a: Passband or sampling length and surface texture parameter symbol and value

- b: Indications of the second and subsequent parameters when multiple parameters are required

- c: Machining method

- d: Crease and its direction

- e: Machining allowance

The descriptors shown below are used when pictorially representing surface roughness. However, generally speaking, the standard conditions, which are shown in red, are omitted, and the indications shown in blue are included only when necessary.

| Symbol | Meaning | Explanatory diagram |

|---|---|---|

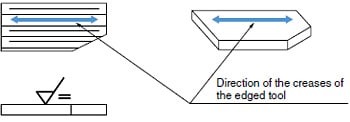

The creases made by an edged tool during machining are parallel with the surface captured in the diagram in which the symbol is written. ExampleShaped surface |

|

|

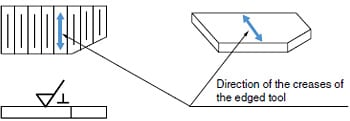

The creases made by the edged tool during machining are perpendicular to the surface captured in the diagram in which the symbol is written. ExampleShaped surface (turned on a lathe; seen from the side), cylindrically ground surface |

|

|

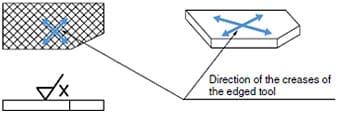

The creases made by the edged tool during machining are at an angle and cross each other on the surface captured in the diagram in which the symbol is written. ExampleHoning finished surface |

|

|

The creases made by the edged tool during machining cross multiple times or have no set direction. ExampleLapped surface, super-finished surface, face-milled or end-milled surface that has been cross fed |

|

|

The creases made by the edged tool during machining form mostly concentric circles in relation to the centre of the surface on which the symbol is written. ExampleFaced surface |

|

|

The creases made by the edged tool during machining form mostly a radial pattern in relation to the centre of the surface on which the symbol is written. |

|