Automotive Industry

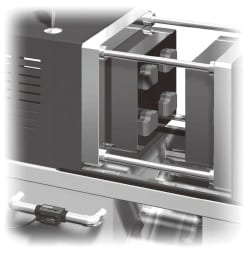

Resin Parts Remaining in Mould

Moulded parts sometimes stick to and remain in the mould due to the electrostatic charge generated by friction with the mould. Due to miniaturisation and thinner designs, moulded parts are lighter and stick more easily. As the shape becomes more complicated, the friction surface with the mould increases and the parts become charged more easily. Furthermore, high-speed moulding machines cause friction at higher speeds, resulting in larger electrostatic charges and greater risk of parts remaining in moulds.

Conventional countermeasures

Handled by workers

- Disposal cost of defective products

- Cost increase due to increased labour cost

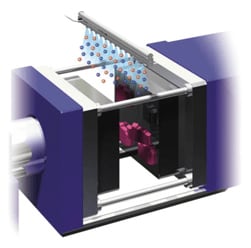

Countermeasures with static eliminators (ionizers)

Costs can be reduced.

Improvements and Effects

Words from the worksite

Reduced disposal cost and labour cost required for disposal

Disposal cost of parts remaining in moulds: 1,000€/month x 12 months = 12,000€/year

Labour cost per line: 200€/month x 12 months = 2,400€/year