Resin & Film Industries

Film Clinging to Blade After Cutting

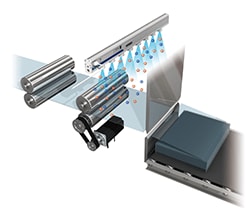

A film is sent to a cutting machine by roll transfer. A certain length of the film is fed to the cutting machine and a blade comes down to cut the film. The film is charged during the roll transfer and sometimes clings to the blade, which prevents proper feeding. Consequently, the blade comes down without a target or the film is cut to incorrect dimensions.

Conventional countermeasures

Handled by workers

- Workers cannot constantly address the problem, so the operating ratio decreases.

- Labour costs are high.

Countermeasures with static eliminators (ionizers)

The operating ratio can be improved and labour costs can be reduced.

Improvements and Effects

Words from the worksite

Reduced disposal cost of defective products and labour cost for work

Production cost during short stop: 1,000€/month x 12 months = 12,000€/year

Labour cost: 25€/hour x Single work time of 2 minutes x 10 times/day x 250 days = 2,000€/year