Electrical Equipment Industry

Damage to Electronic Components During Transfer of Electronic PCBs

In the transfer process, electronic PCBs are charged with static electricity by friction with or separation from the conveyor.

At the point where the PCB leaves the conveyor, the electrostatic capacitance of the PCB drops, resulting in an increase of the charging potential. This causes electrostatic discharge (ESD) which damages the electronic components mounted on the PCB.

Conventional countermeasures

None

- Disposal cost of defective products

- Risk of the release of defective products

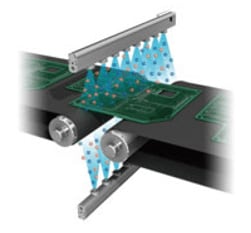

Countermeasures with static eliminators (ionizers)

An ionizer can reduce disposal cost and reliably prevent the production of defective products.

Improvements and Effects

Words from the worksite

Reduced disposal cost of PCBs

Disposal cost per line: 1,000€/month x 12 months = 12,000€/year

In addition, the measure is also effective for improving the yield rate in the later processes such as reduced labour for re-inspection.