Resin & Film Industries

Improperly Positioned Labels on Resin Bottles

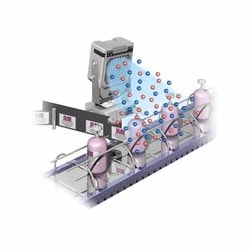

Resin bottles are charged with static electricity during the moulding and transfer processes. The labels are charged during roll transfer as well as by the separation from the release liner when they are affixed onto the bottles.

The repulsion and attraction between the charged bottle and label cause the label to shift from the proper position.

Conventional countermeasures

Inspection

- It can prevent the release of defective products, but it cannot improve the yield rate of the product.

Countermeasures with static eliminators (ionizers)

An ionizer can reduce the waste of material costs and improve the yield rate.

Improvements and Effects

Words from the worksite

Reduced disposal cost due to defective labelling

Disposal cost due to defective labelling: 400€/month x 12 months = 4,800€/year

In addition, there are other resulting benefits of improved reliability.