Electrical Equipment Industry

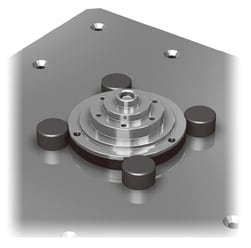

Dust Adhesion During Assembly/Inspection of HDD Motors

Dust and other particles adhere to workpieces in the bearing press-fitting, magnet mounting, run-out inspection, and appearance inspection process, resulting in the need for a dust removing process.

It is difficult to remove dust adhering with static electricity using an air blow. Even if the dust can be removed, it may adhere again.

Conventional countermeasures

Handled by workers

- Cost rise due to increased labour cost

- Long takt time

Countermeasures with static eliminators (ionizers)

It reduces cost and saves takt time.

Improvements and Effects

Words from the worksite

Reduced labour cost for addressing the problem

Labour cost per line 200€/month x 10 lines x 12 months = 24,000€/year

Although calculation of the takt time is difficult due to the relation with the previous and next lines, it has definitely been improved.